Introduction

Currently, the world faces environment, energy and sustainable development problems 1. The continuous dependence on fossil fuels resources such as coal, natural gas and petroleum has caused their depletion, global climate change and the emission of greenhouse gases 2,3. Hence, efforts have been globally made by researchers to search for alternative means of generating renewable and sustainable energy 4,5. Among RE resources, BM has been found to have the potential to reduce greenhouse gas emissions and maintain a balance in CO2 release and absorption 6,7. Diverse BM materials, which are C neutral and abundantly available, mostly as residues, have been considered promising resources available to generate alternative transport fuels, heat, high valued-biochemical products and electricity 8,9. IEA 10 reported that BM energy accounts for approximately 14% of the global total primary energy supply. Broadly, BM feedstock can be classified as first and second-generation. First-generation BM samples are those from food crops such as sugar cane, palm, soya bean and corn. Their continued use could precipitate an unhealthy competition between food and fuel supply, and deplete the land area available for food cultivation 11. This represents a significant setback for the use of food crops in the frontline of BF research, since the corn-based industry has been considered unable to meet global B-O demand 12.

On the other hand, second-generation BM sources are those obtained from non-food crops, such as weeds, straws, herbs and woods 13,14. One of their main demerits is that the exploration processes are less well-developed and more complex than those of the first-generation BM. However, keen attention is on second-generation BM, since they are available as residues from agricultural, industrial and even municipal activities 15,16. Another significant advantage of BM residues is that they help to meet waste management, energy security and climate change challenges, stopping the fuel vs. food debate 17. Developed countries, such as EUA and some in Europe, have advanced their BM-based technology for the sole purpose of energy generation. Unfortunately, Nigeria, one of the developing countries with severe energy challenges, has not taken the advantage of RE use, despite the abundant availability of BM resources 18,19. Previously, it was stated by (20) that the practice of waste management which often employs, for instance, dumping into drainages or river channels, causes health and environmental risks.

BM, a promising RE source, is an organic matter obtained from biological organisms, such as wood, plants, herbaceous species, animal remains, industrial and agricultural residues 21. Plant species are the largest BM source 22. Their compositional variations affect pyrolytic products nature, quality and quantity. From studies, dry BM annually produced is estimated to be 220 billion tons 23. BM contains a reasonable amount of water and other significant elements such as S, N, P and Cl. Hence, the type of BM used in the production of pyrolytic products plays a major role in BF production 24.

To this end, BM of LC, which is regarded as the main building block for all plants cell walls, remains the most promising RE resource on earth. LC sources are classified as primary (cotton, sugar cane, rice husk, wheat straw and bagasse), secondary (forest wastes, such as sawdust, chips, wood and bark) and tertiary (dried manure and industrial residues) 25. BM samples of LC possess higher VM than that of coal. VM differs among various materials 26, which explains thermochemical devolatilization reactions. Cl, HC and LN are the main BM components, which differ in the way they decompose. These LC constituents are chemically bonded together by non-covalent force. The ease with which these LC components degrade is largely attributed to their structural stability 27.

In Py process, LN is the most difficult one to be pyrolyzed, followed by Cl and HC 28. Hence, 29 reported that Cl and HC, at 400 and 200 ºC, respectively, have higher WL than that of LN, which volatilized at 900 ºC. It was concluded that BM composition influences the T at which maximum B-O is produced.

For this study, the selected BM samples were broadly classified into woody (IS and MB) and non-woody (CS and EG) materials. They were selected for physical, chemical, structural composition and thermal characterization.

Mahogany, from Swietenia genus, is a tropical hardwood with reddish-brown straight-grained timber that makes for beautiful carving. Typically, it grows up to 150 feet in height and 12 feet in diameter. The bark is fairly smooth and dark in color. This tropical tree can be found in many areas like beaches, teak forests and city streets. As waste, it has a volume discharge from 50 to 60% 30, and relatively high HC (27.37%), Cl (47.26%) and LN (25.82%) contents 31. Hence, using MB could be a promising prospect in B-O production.

Iroko wood is a large hardwood tree species from Milicia genus and Moraceae family. It can be mainly found on tropical Africa west coast. It can live up to 500 years, with a size from 100 to 130 feet, and a diameter from 3 to 5 feet. Iroko has great resistance to mechanical wear, interesting wood figures, good dimensional stability and great resistance to biological agents. Due to its durability and color, it is used for furniture, boats, piles, railroad crossties and other marine works 32. IS constitutes a good BM source for thermochemical processes 33.

Being extensively produced in developing countries, CS is regarded as one of the main agricultural wastes 34, and an attractive BM option for thermochemical processes 35. Nearly 1.22-1.27 million tons per year CS are produced by China. Thus, as a policy, China strongly encourages CS use for energy purposes.

Likewise, EG has high BM production and low input requirements, which is why it adapts to a wide range of land types and climate change zones 36. It is a perennial tropical grass primarily used as forage, which can withstand continuous harvesting/cutting, and still regenerate 37. EG maturity period is about three months, and it has a height from 1 to 1.2 meters. It is a tropical C4 bunch grass, with high BM yield and growth rate. Under optimal conditions, it is able to yield 60 tons/ha/yr of dry BM. It has low AC (2.6-3%) and N, and high LN and fiber 37. EG is a C-negative and low-cost alternative to fossil fuels, with great potential for energy production 38. Furthermore, it is regarded as a commercial crop, and known for its resilience and ability to perform photosynthesis during winter periods. Thus, it is a promising BF source.

It has been reported that BM wastes are highly available in Nigeria, with an estimated seven million m3 per year of forestry residues, from sizing and logging operations, while sorghum cultivation (non-woody) was estimated at 11.37 million tons 39,18. Hence, upgrading BM wastes through a fast Py process is paramount for energy generation in Nigeria, since this could help transforming the wide spread of BM residues production into useful BF products, and reducing trees felling.

Materials and methods

BM materials sources

Iroko (Milicia excelsa) and mahogany (Swietenia macrophylla) woody logs were procured from a timber processing plant, while CS (Zea mays), which consist of stalks, leaves and cobs of maize plants, and EG (Pennisetum purpureum) were sourced from a farm site in Omu-Aran town, Kwara State, Nigeria, from late October to early November 2020. Fig. 1 shows the various BM samples used for this study.

BM harvesting and handling

Matured EG was collected into sack bags in October 2020. Iroko sample was milled to sawdust. The bark from mahogany log was stripped and milled. After harvesting the matured corn grain, CS, which is the residue, was sourced, manually cut at 8-10 cm above ground level, and collected into sack bags.

BM sizing, sieving and storage

Thereafter, the abovementioned raw materials were transported to the Department of Civil Engineering, Landmark University, Omu-Aran, Kwara State, where they were dried indoors, to prevent contaminants like sand and woods particles, or debris, for ten working days (8 h per day), with an average T of 35 ± 2 ºC. The samples were dried in an oven for 5 h, at a T of 105 ± 2 ºC, to aid milling. The materials were pulverized in a ball mill to particle sizes from 0.2 to 2.0 mm. Prior to analyses, the samples were stored at room T in Ziploc bags. After pre-treatment, a portion of each BM sample was transported, for characterization, to Rolab Research and Diagnostic Laboratory, Ibadan.

Proximate and elemental analyses

AC was determined in a muffle furnace (Carbolite, England, S33. 6RB), at 550 ºC, for 8 h, in line with ASTM E1755-01. VM was assessed at 900 ºC, for 8 min (ASTM E872-82). MC was determined following ASTM E 1358-97. FC content was calculated by the difference 40. The elemental analysis was conducted with LECO CHN 2000, for determining C, H and N contents (ASTM D5373-21). S content was determined by keeping 1.5 g of the samples in a flame photometer, above 1000 ºC (ASTM D4239-11), while O was calculated by the difference.

Structural composition analysis

Conventional NREL methods were used to perform BM samples compositional analysis. For obtaining the extractives amount, 100 mL acetone were added to BM samples (at 70 ºC, for 20 min). Then, they were dried in a Genlab oven (at 105 ºC, for 2 h), to obtain a constant weight 41. HC amount was obtained by adding NaOH to the extractive-free samples, and boiling them with distilled water (at 80 ºC, for 3.5 h), before drying (at 105 ºC), to get a constant weight. LN amount was determined by adding H2SO4 to the samples, and boiling them at 100 ºC, for 1 h. Then, they were oven dried (at 105 ºC), to obtain constant weight samples, while Cl content was obtained by the difference.

HHV

HHV of BM samples was determined using a Mohan Brothers bomb calorimeter model (ASTM DIN 51900), whereby 1 g of the oven-dried samples was used for charging the bomb.

TGA

TGA (4000 Perkin Elmer, USA) with N purge gas (50 mL/min) was used for decomposition tests. 15 mg of the samples were filled into an Al crucible, and then heated from 35 to 850 ºC, at a steady heating rate of 10 ºC/min 42,43.

Results and discussion

BM wastes used for bioenergy applications and/or for chemical extraction are usually preceded by chemical analysis that gives vital insight into physical and chemical properties, and energy potential of the prospective feedstock. Table 1 presents a summary of the average values of the proximate and ultimate analyses.

Table 1: Proximate and ultimate analysis of woody and non-woody BM samples.

| Samples | Proximate analysis (wt%) | Ultimate analysis (wt%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MC | FC | VM | AC | C | H | N | O | S | |

| CS | 0.40 ± 0.2 | 20 ± 0.1 | 76.24 ± 0.4 | 3.36 ± 0.2 | 46.65 ± 0.3 | 5.95 ± 0.5 | 0.69 ± 0.1 | 43.61 ± 0.2 | 0.1 ± 0.03 |

| EG | 0.86 ± 0.4 | 20.96 ± 0.4 | 73.27 ± 0.2 | 5.9 ± 0.1 | 43.44 ± 0.1 | 5.6 ± 0.3 | 0.68 ± 0.2 | 47.95 ± 0.1 | 0.02 ± 0.001 |

| IS | 0.42 ± 0.2 | 17.84 ± 0.3 | 77.96 ± 0.7 | 3.78 ± 0.1 | 50.06 ± 0.1 | 5.63 ± 0.3 | 0.04 ± 0.002 | 46.25 ± 0.1 | 0.33 ± 0.002 |

| MB | 1.3 ± 0.05 | 15.7 ± 0.2 | 79.04 ± 0.7 | 3.96 ± 0.3 | 50.81 ± 0.1 | 5.46 ± 0.3 | 0.13 ± 0.01 | 47.55 ± 0.5 | 0.05 ± 0.003 |

MC, FC, VM and AC ranged from 0.4 to 1.3%, 15.7 to 20.96%, 73.2 to 79.04% and 3.36 to 5.9%, respectively. These values were similar to those in literature 34,33,40. EG had highest AC (5.90%) and FC (20.96%), while CS had the lowest AC (3.36%), which was within the range (3.6 to 7.0%) presented by 34. This result is also comparable to those achieved by 22 and 24, in which AC range for woody (Afara and Iroko) and agricultural BM species was 0.61-5.03% and 3.25-7.5%, respectively. This low AC in CS makes it more desirable for Py process. Hence, CS was recommended for this study, since 44 and 45 reported that low AC improves B-O yield quality, which results in better economic performance.

Due to the presence of higher mineral contents (K and P), EG had the highest recorded AC. During Py, this may lead to slagging, fouling, erosion and catalytic cracking into non-condensable gases, consequently reducing B-O yield of EG, which makes it relatively undesirable 46.

In this work, VM of CS (76.24%) was similar to values reported by 34 (74.61%) and 47 (77.14%). VM content for MB (79.04%) and IS (77.96%) agrees with findings by 33 (77.14% and 75.74%, respectively) and 24. High VM may increase devolatilization reactivity and HV, which results in a high B-O yield 48. BM samples had relatively low MC (from 0.4 to 1.30%), and CS (0.4%) presented the lowest value, which indicates good Py performance 49. High FC and low MC of CS could also improve hydrocarbon production.

CC was the highest (50.81%) for MB (woody) and the lowest (43.44 %) for EG (non-woody), which is consistent with findings from literature 50. All samples had N and S contents lower than 1, which agrees with results from literature 51, and indicates that BM samples are eco-friendly and useable for thermochemical processes.

BM samples structural composition and HV are presented in Table 2.

Table 2: BM compositions and HHV.

| Sample | Cl(%) | HC(%) | LN(%) | HHV (MJ/kg) |

| CS | 47.56 | 27.12 | 25.96 | 24.8 |

| IS | 44.50 | 28.60 | 26.52 | 22.8 |

| EG | 45.22 | 28.92 | 25.68 | 19.7 |

| MB | 47.22 | 26.82 | 25.75 | 24.6 |

The four BM samples had high Cl (which ranged from 44.50 to 47.56%) and HC contents, and low LN values. CS had the highest Cl content (47.56%), though the value reported by 52 was relatively lower (40%). Cl and HC contents for CS agreed with the values (48 and 29%, respectively) reported by 53,54. Thus, CS is the most suitable for Py, since Cl and HC contents are the two main BM components that favor B-O high yield.

HV ranged from 19.7 to 24.8 MJ/kg. EG had lowest HV (19.7 MJ/kg), while CS had HHV (24.8 MJ/kg), which agrees with its 18-23 MJ/kg HV value reported by 55. This HV was due to CS high CC and low AC and MC, which are main heat sources 48,56. Investigated BM samples performed well for bioenergy production, through the fast Py process. However, CS was selected, since it has optimal properties for achieving best B-O production, with respect to quantity and quality.

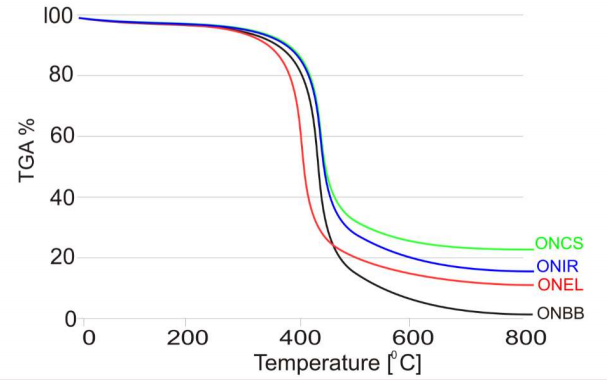

TGA is a laboratorial technique used to deduce BM physical and chemical changes brought about by T, at a given HV, and within a predefined range 57. Fig. 2 shows thermograms for CS, IS, EG and MB pyrolytic decomposition in N, at 50 mL/min, in air atmospheres, and a heating rate of 10 ºC/min.

Generally, thermal degradation of BM species with LC involves dehydration (moisture removal), devolatilization (active Py zone), and solid decomposition/char formation stages, as clearly shown on thermograms. At dehydration stage, the four BM samples underwent slight WL of about 4.25 wt%, due to moisture evaporation, from 35 to 150 ºC 58. The next stage was a barely visible zone assigned to HC degradation, from 220 to 230 ºC 59. 60 also reported that, at the second stage, imperceptibility is possibly due to HC and Cl thermal decomposition overlapping. Cl is fast and completely degraded from 260 to 350 ºC, turning into to char. Therefore, this stage is a significant zone, since Cl and HC constituents were predominantly decomposed.

Fig. 2 shows that MB sample exhibited the highest WL, while CS had the lowest. This agrees with findings in literature for woody and non-woody BM samples 61,62. From this point, all Cl and HC are completely degraded 42. However, LN degradation occurs within a T high range and continues to 850 ºC 42.

The third stage involves the formation of carbonaceous (production of syngas and carbonization) elements. Herein, less WL is observed, above 600 ºC 63. At this point, heavier chemical structures devolatilize. MB suffered residual WL (2.3%/min) at final T of 850 ºC, though 57 reported a carbonization phase from 450 to 800 ºC. Therefore, TGA profile in Fig. 2 reveals that, for the analysed BM samples Py process, high B-O yield occurred within a T range from 400 to 600%. However, the variations in the obtained results, compared with published literature (Table 3), were due to BM soil type, geographical location and intrinsic composition 64.

Table 3: BM feedstocks for thermochemical conversion: previous works vs. present study.

| S/N | Ref. | Results |

|---|---|---|

| 1 | 50 | They examined the screening of EA, IC, TA, ES and AS samples of BM, based on Pc and compositional analyses, to determine their energy potential. EA had the lowest MC (8.30%), and TA the highest (13.95%). AC was seen to be highest for AS (8.1%) and lowest for EA (3.7%). CC was the highest for TA (52.90%) and the lowest for EA (41.0%). . |

| 2 | 46 | The study considered availability and ecological perspective for IC bioenergy potential, in Brunei, Darussalam. Characterization was done to determine Pc, structural, compositional and HV analyses of IC. Proximate analysis results were: MC: 6.8%; VM: 72.01%; FC: 18.21%; and AC: 2.97%. Elemental analysis data were: C: 44.38%; H: 5.65%; N: 0.82%; O: 49.06%; and S: 0.09%. The compositional result was: HC: 25.13%, Cl: 44.49% and LN: 17.89%. HHV was 18.39 MJ/kg. |

| 3 | 51 | They carried out MB characterization through proximate, ultimate and HHV analyses. The characterization results revealed that MB had: MC: 5.8%; VM: 79.11%; FC: 13.85%; and AC: 1.24%. The elements were: C: 55.30%; N: 0.34%; O: 39.26%; and S: 0.60%. HHV was 21.26 MJ/kg. |

| 4 | 65 | They compared five different BM feedstock materials (rice husk, rice straw, bamboo, sugar cane bagasse and neem bark), to determine their bioenergy potential, through proximate and elemental analyses. The results were: rice husk (VM: 72%; FC: 5.5%; AC: 22.5%; C: 35.9%; H: 5.1%; N: 0.26%; and O: 58.8%); rice straw (VM: 81.1%; FC: 6.3%; AC: 12.6%; C: 38.0; H: 5.75%; N: 0.65%; and O: 55.60%); bamboo (VM: 77.73%; FC: 15.99%; AC: 6.28%; C: 42.16%; H: 5.74%; N: 0.37%; and O: 51.73%); sugarcane bagasse (VM: 75.67%; FC: 16.9; AC: 7.40%; C: 40.59%; H: 5.89%; N: 0.42%; and O: 53.1%); and Neem bark (VM: 79.8%; FC: 15.3%; AC: 4.8%; C: 43.4%; H: 6.1%; N: 0.26%; and O: 50%). |

| 5 | This study | The preliminary investigation of four woody (IS and MB) and non-woody (CS and EL) BM samples (from Omu-Aran Kwara State, Nigeria) that were subjected to Pc, structural compositional, HV and thermal analyses, was performed. Proximate results showed that MC ranged from 0.4 to 1.3%, FC from 15.7 to 20.96%, VM from 73.2 to 79.04% and AC from 3.36 to 5.90%. Elemental analysis revealed that woody BM samples had highest CC. Structural composition results showed that CS had highest Cl content (47.56%) and IS the lowest (44.50%). CS had HHV of 24.8 MJ/kg. EG had lowest HV of 19.7 MJ/kg. BM samples thermal decomposition behavior showed that MB had highest decomposition, while CS had the lowest. Variations obtained from this study, in comparison with published literature, were probably due to soil type, geographical location and intrinsic composition of BM samples. |

AS: Arundinella khasiana Nees ex Steud; EA: Eragrostis airoides; ES: Echinochloa stagnina; IC: Impereta cylindrical; TA: Typha angustifolia.

Conclusions

This study investigated Pc, structural composition and thermal analysis of woody and non-woody BM samples, to select those that can improve B-O yield quality via Py process. All investigated BM samples showed high energy potential for Py process. The lowest AC values were obtained for CS (3.39%) and MC (0.4%), which improved their B-O yield quality. BM samples thermal decomposition behavior showed that MB had the highest decomposition, while CS had the lowest. The energy potential of the four different BM samples containing LC, for use as BF, was herein determined. This could help in the selection of appropriate materials for the conversion process, in further studies. Hence, CS is herein recommended for a fast Py process, due to its high energy potential.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article. The corresponding author can provide raw data supporting this study upon reasonable request.

Authors’ contributions

E. Onokpite: conceived the theory, formulation and methodology; sourced and analyzed data; prepared and edited the manuscript; handled the submission and review processes. A. O. Balogun: conceived the theory, formulation and methodology; sourced and analyzed data; prepared and edited the manuscript. A. O. Onokwai: sourced and analyzed data; prepared and edited the manuscript; handled the submission and review processes. M. Oki: conceived the theory, formulation and methodology; sourced and analyzed data. E. B. Omoniyi: conceived the theory, formulation and methodology; sourced and analyzed data. S. A. Olabisi: analyzed the data, edited the manuscript and review processes. The results were discussed and commented on by all authors. J. O. Oyebanji: prepared and edited the manuscript; handled the submission and review processes. The results were discussed and commented on by all authors.

Conflicts of interest

The authors declare no conflict of interest.

Abbreviations

AC: ash content

ASTM: American Society for Testing and Materials

BM: biomass

BF: biofuel

B-O: bio-oil

CC: carbon content

Cl: cellulose

CS: corn stover

EG: elephant grass

FC: fixed carbon

HC: hemicellulose

HHV: highest heating value

HV: heating value

IEA: International Energy Agency

IS: iroko sawdust

LC: lignocellulose

LN: lignin

MB: mahogany bark

MC: moisture content

NREL: National Renewable Energy Laboratory

Pc: physicochemical

Py: pyrolysis

RE: renewable energy

T: temperature

TGA: thermogravimetric analysis

VM: volatile matter

WL: weight loss