Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Corrosão e Protecção de Materiais

versão impressa ISSN 0870-1164versão On-line ISSN 2182-6587

Corros. Prot. Mater. vol.35 no.2 Lisboa dez. 2016

https://doi.org/10.19228/j.cpm.2016.35.05

ARTIGOS

Atmospheric corrosion of patinated silverwork: a conservation challenge

A corrosão atmosférica de objectos em prata com pátina: um desafio para a conservação e restauro

Isabel Tissot 1,*, Olinda C. Monteiro 2, Maria Alexandra Barreiros 3 and Maria Filomena Guerra4

1LIBPhys - UNL 2829-516 Caparica, Portugal & Archeofactu, Rua do Cerrado das Oliveiras, nº 14, 2ºDto, 2610-035 Amadora, Portugal. * A quem a correspondência deve ser dirigida, e-mail: isabel.tissot@archeofactu.pt

2Centro de Química e Bioquímica, Faculdade de Ciências, Univ. de Lisboa, Campo Grande, 1749-016 Lisboa, Portugal, e-mail: ocmonteiro@fc.ul.pt

3LNEG, LEN/UER, Estrada do Paço do Lumiar, 22, 1649-038 Lisboa, Portugal, e-mail: alexandra.barreiros@lneg.pt

4 ArchAm - UMR 8096 CNRS, MAE, 21 allée de l'Université, 92023 Nanterre, France, e-mail: maria.guerra@cnrs.fr

ABSTRACT

Patination has been frequently used by jewellers to modify the colour of silver alloys. By application of a solution of sulphur compounds, blackish or bluish surfaces can be obtained, but the intentionally produced silver-sulphur compounds are chemically similar to the atmospheric corrosion products that develop on silver alloys. The conservation of patinated silver objects, such as Art Nouveau jewellery, raises thus analytical challenges. In order to define accurate conservation treatments, the patina and corroded surfaces characterisation is mandatory. In this study, sterling silver samples were patinated and subjected to corrosion by immersion in a sulphide containing solution. The identification of the chemical compounds present on the patinated sterling silver before and after corrosion was carried out by UV-visible spectrophotometry, X-ray diffraction and scanning electron microscopy with energy dispersive X-ray spectrometry. Data obtained suggest a two-stage corrosion process: a decrease of the silver compounds patina thickness caused by its dissolution, followed by the formation of corrosion products with different compositions and morphologies containing silver and copper sulphur compounds.

Keywords: Patination, Silverwork, Sterling Silver, Atmospheric Corrosion, Conservaon

RESUMO

A aplicação de pátinas em objetos de prata, para produzir uma superfície de cor acinzentada a preta, é uma técnica de decoração frequentemente utilizada por ourives. A pátina é obtida por aplicação de uma solução, normalmente à base de compostos de enxofre, formando um revestimento constituído por compostos de prata e enxofre. Sendo estes compostos semelhantes aos produtos de corrosão atmosférica da prata, a conservação de objetos corroídos em prata com pátina levanta questões relacionadas com a incompatibilidade de tratamentos, resultantes da semelhança entre os compostos formados intencionalmente e os da corrosão atmosférica. Para definir tratamentos de conservação específicos, é fundamental caracterizar as superfícies com pátina e com pátina corroída. Neste estudo, amostras de prata sterling com pátina foram corroídas por imersão numa solução contendo sulfuretos. A caracterização das superfícies com pátina antes e após corrosão foi realizada por espectrofotometria de UV-Vis, difração de raios-X e por microscopia eletrónica de varrimento com espectrometria de raios-X dispersiva em energia. Os resultados revelaram que a corrosão das amostras de prata sterling com pátina compreende a dissolução da pátina seguida da formação de produtos de corrosão com composições e morfologias distintas contendo sulfuretos de prata e sulfuretos de cobre.

Palavras-Chave: Liga de Prata, Pátina, Corrosão Atmosférica, Conservação

1. INTRODUCTION

Patinated silver is characterised by a blackish or bluish surface intentionally produced by an oxidiser, usually a sulphur compound [1]. This decoration technique, frequently applied on silver jewellery and ware, had a large diffusion in France in the early 20th century [2]. Inspired by the neo-gothic and neo-renaissance styles, jewellers and silversmiths applied patinas in selected areas of silver objects. Their aim was to obtain surfaces that looked like the tarnished surfaces of ancient objects. In the mid-19th century, the spread of Japonism in Europe brings to jewellery the application of patinas inspired by the Japanese Shakudo1 and Shibuichi 2[2]. René Lalique, one of the most representative artists of the Art Nouveau movement, has extensively used patinas to create colour contrasts enhancing the three-dimensional perception of his jewellery masterpieces [5].

Silver patina recipes used liver of sulphur (a potassium sulphide solution [2] ) and other sulphides and polysulphides solutions [6] . Later, selenides frequently applied to blacken copper-based alloys [7], were also used in silver patination. Over time, corrosion develop on patined objects. The optical properties of their surface are modified by the formation of corrosion products with various nuances of grey, like the original patina hue. Since the atmospheric corrosion of patinated silver surfaces has a direct influence on their perception [8], because colour has a role in the material identification, the objects require an accurate conservation treatment.

The conservation of the surface effects created by the patinas is a complex task. Although the patina recipes are known, the detailed identification of the compounds formed at the objects surface is still missing. In addition, the atmospheric corrosion products (including Ag2S and AgCuS complexes) [9] and the compounds produced by the patination processes using sulphide solutions should be similar. The missing information on the nature of the corrosion products formed, prevents the application of standard conservation treatments that could remove the patina. Due to an incorrect distinction between intentional patination and corrosion, several silver objects have in fact already lost their original decoration [2].

The present work attempts to be a first approach to the study of the atmospheric corrosion of patinated silver. Samples of sterling silver (92.5 wt% Ag; 7.5 wt% Cu) were patinated with selenide compounds and corroded by immersion in a sulphide containing solution. Data obtained by different analytical techniques for the samples before and after corrosion were compared and discussed.

2. METHODOLOGIES AND INSTRUMENTATION

Samples of sterling silver, the main alloy used to fabricate silver jewellery and ware, were patinated and then corroded. The samples were roughly abraded before patination [9]. The patinated samples were then corroded by immersion in a sulphide containing solution. To simplify the surface characterisation procedure, the samples were patinated with a selenide solution. Contrary to the compounds formed when using liver of sulphur, the silver-selenium compounds resulting from the use of selenide based compounds are not related to naturally occurring corrosion products [7] . Since Ag2Se belongs to the family of silver chalcogenides Ag2 E (E = S, Se, and Te), the compounds formed are chemically similar to sulphide compounds.

The colour, the morphology and the composition of the surfaces before and after corrosion were characterised using UV-Vis spectrophotometry (UV-Vis), scanning electron microscopy (field emission gun) with energy dispersive X-ray spectrometry (SEMFEG-EDS) and X-ray diffraction (XRD).

2.1 Samples preparation

Black patina was applied on sterling silver (Ag925) samples of 1.5 cm 2area and 1 mm thickness, acquired from a local jeweller supplier. The patination process was carried out by a jeweller using a commercial solution containing sodium selenite (Na2 SeO3 ). The samples were immersed in the solution during 1 minute, at room temperature, and then rinsed with water and dried. This process was repeated 6 times until a homogeneous grey-black colour surface was obtained.

The patinated samples were submitted to accelerated corrosion by immersion in a 0.1 M Na2S aqueous solution during 120, 240 and 360 minutes.

2.2 Surface characterisation

The surface of the sterling silver samples was characterised before and after patination and after corrosion. Elemental analyses were carried out by XRF to verify the alloy composition and homogeneity. Data obtained showed an homogeneous silver alloy containing 93.1 ± 0.1 wt% Ag and 6.9 ± 0.1 wt% Cu. The optical characterisation of the patinated samples before and after corrosion was carried out by UV-Vis and the surface morphology characterised by SEM-FEG-EDS. The crystalline compounds of the patina and the corrosion products were identified by XRD.

XRF: The XRF was carried out with a Tornado M4 from Bruker comprising an anode of Rh with a poly-capillary lens, offering a spot size down to a 25 µm at a working distance of 10 mm, coupled to a XFlash® silicon drift detector (SDD) technology, with a 30 mm² sensitive area and an energy resolution < 145 eV. Spectra were collected for 300 s with the X-ray tube operating at 50 kV and 300 µA. The elemental quantification was performed using ESPRIT software.

UV-Vis: The UV-Vis spectrophotometry data was obtained by using a Shimadzu UV-2450PC spectrometer. The diffuse reflectance spectra were recorded with a detecting wavelength ranging from 220 to 1400 nm. Absorption data were calculated from reflectance data using Kubelka-Munk equation.

SEM-FEG-EDS: The surface morphology was observed with a SEM-EDS Philips XL 30 FEG equipment operated with acceleration voltage from 10 to 15 kV. Semi-quantitative elemental composition was obtained with an EDS (EDAX) system equipped with a Si(Li) detector and a 3 µm super ultra-thin window (SUTW), allowing detection of light elements. Spectra were collected in spot mode analysis for 300 s acquisition time.

XRD: The analysis by XRD were obtain using a Philips Analytical X-ray diffractometer (PW 3050/60) with automatic data acquisition (X'Pert Data Collector (v2.0b) software) with a Cu Ka radiation (l= 0.15406 nm) operated at 40 kV, 30 mA. The data were collected with a step size of 0.01 and an acquisition time of 200 s deg . Powder diffraction files were obtained from the Pearson's Crystal Database.

3. RESULTS AND DISCUSSION

3.1 Characterisation of the patina

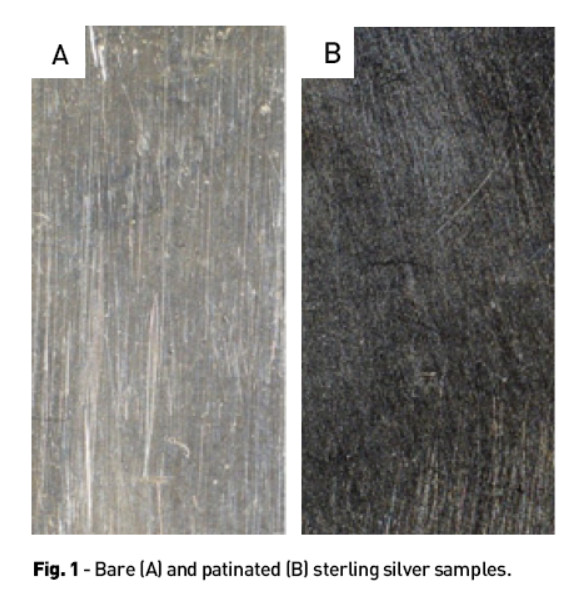

The patination process grey-blackened the sterling silver surfaces, keeping the metallic lustre that is characteristic of the polished metal surfaces, as shown in Fig. 1.

The UV-Vis data obtained for the bare and patinated sterling silver samples (Fig. 2) show for the latter the presence of a well-defined band at 309 nm and a broaden band between 320 and 390 nm. These bands can be attributed to the presence of Ag2 Se [10] .

The presence of these bands and the shift towards lower wavelengths can be ascribed to particles with distinct shapes or sizes [11, 12].

The SEM secondary electron (SE) images of Fig. 3A show the bare sterling silver surface where it is possible to distinguish the grain boundaries characteristic of the metal solidification process [13]. Evenly distributed pores due to gas porosity, a casting process defect, can also be seen [14]. The surface of the patinated sterling silver is characterised by a homogeneous film composed of spherical and tubular particles present in recessed areas (Figs. 3B and 3C). The different particle shapes can be ascribed to distinct crystalline structures of Ag2Se 2 [12] . Data also suggest that the film is composed by overlapping layers, as shown in Fig. 3C.

Table 1 summarises the elemental composition of the patina obtained by EDS. In this table, the Se, S, Ag and Cu contents correspond to average values of multiple measurements. The unexpected occurrence of S in the patina can be justified by its presence in the solution used for the patination process. The results obtained also suggest that tubular formations have higher Se and lower Cu contents, when compared to the spherical particles and the plane film areas.

Fig. 4 illustrates the diffractograms obtained by XRD for the bare and patinated sterling silver. Ag Se was identified as the main crystalline compound of the patina, confirming the UV-Vis and the SEM-EDS results. Although the presence of sulphur was identified by EDS, no S containing compound was detected by XRD. This can be justified either by the presence of small amounts of S containing compounds, agreeing with the EDS results, or by their noncrystalline structure.

3.2 Characterisation of the corroded patina

Fig. 5 shows the patinated samples of sterling silver before and after corrosion. All the corroded samples have a grey-blackish colour with a dull aspect, but nuances can be perceived. The surface of the sample immersed during 360 minutes (Fig. 5D) is darker.

Fig. 6 compares the UV-Vis spectra of the patinated sterling silver samples before and after corrosion. The similarity of the spectra profiles does not allow to identify differences among the samples surfaces. In addition, the surface roughness can justify the differences observed for the absorption intensities.

The morphologies of the corroded and non-corroded surfaces observed by SEM are distinct. Fig. 7A shows a heterogeneous surface with gaps, indicating an alteration of the patina, for the sample corroded during 120 minutes. The abrasion marks become more visible for this sample. This fact suggests the patina dissolution, which induces a thickness decrease.

With the increasing of the immersion time, the samples surfaces become more homogeneous suggesting the formation of a corrosion film. On the roughest areas, nanosheets and microspheres that resemble copper sulphides morphologies can been observed (Fig. 7B and 7C) [15, 16].

Table 2summarises the elemental composition of the plane areas and the morphology of the particles observed on the corroded surfaces. The plane areas of both the corroded and non-corroded surfaces have similar Se and S contents, but the Cu content is lower for the corroded surfaces. The Se and S contents for the corroded samples are higher in the particles than in the plane areas.

Fig. 8 shows the diffractograms obtained by XRD for the different corroded samples. The intensity of the Ag diffraction peak at 38.1º increases for the sample immersed 120 minutes, suggesting the patina dissolution. For higher immersion times this peak decreases, which can be related to the formation of corrosion products at the surface, increasing the corrosion film thickness. With the immersion time increase, a peak at 38.6º, which can be ascribed to the presence of Cu2S, overlaps with the Ag diffraction peak. However, the simultaneous identification of the different compounds is complex. The Ag2Se, Ag2S and Cu2S diffraction patterns are similar and the presence of broaden diffraction peaks suggests the existence of small size particles and non-crystalline compounds [17].

Table 3 lists the crystalline compounds identified so far, including Ag2S and Ag2Se. The presence of Cu2S was identified in the samples immersed during 240 and 360 minutes. These results are in agreement with the morphologies identified by SEM. It can be suggested that the corrosion mechanism of the patinated silver comprises firstly a partial dissolution of the patina, followed by a nucleation of new compounds. In these compounds, that are distinct from those that characterise the original patina, Cu2S is included.

4. CONCLUSIONS

The corrosion developed on the surface of patinated silver jewellery and ware changes the appearance of the original patina, because the corrosion products that are formed result in a layer that appears in various nuances of grey with a dull aspect. The effect created by the application of an artificial patina is then lost, altering the object appearance and, therefore, its perception. Hence, to define an accurate conservation treatment, it is necessary to fully characterize the original patina and the corroded surfaces.

Studies considering the characterisation of silver patinas and the atmospheric corrosion of patinated silverwork are scarce. In this work, sterling silver samples patinated using a selenium compound solution and then corroded by immersion in a Na2S solution, creating a high sulphide environment, were studied. The patina obtained has a lustred grey-blackish colour that is composed of overlapping layers of Ag2Se, identified by SEM and XRD. The presence of Ag2Se particles of different sizes and shapes could be characterized by UV-Vis. After corrosion by immersion in a Na2S solution, the corroded samples have the same colour as the non corroded ones, but the first became dull. SEM images of the surfaces show a decrease of the patina thickness caused by dissolution for the sample immersed during 120 minutes. XRD analysis confirmed the patina dissolution, because the intensity of the diffraction peak of silver at 38.1º decreased. For the sample with the highest immersion time (360 min), an increase of the corrosion film thickness with the formation of compounds of distinct morphologies, like nanosheets and microspheres, could be observed and ascribed to the presence of Cu S identified by XRD and SEM.

In conclusion, this first approach to the corrosion of patinated silver alloys suggests a corrosion process that can be divided into two stages: firstly there is a dissolution of the patina that is followed by the formation of corrosion products containing silver and copper sulphur compounds.

ACKNOWLEDGMENTS

The authors gratefully thank Michel Dubus from the C2RMF (Centre de Recherche et de Restauration des Musées de France) and Victoria Corregidor from the IST/CTN (Instituto Superior Técnico/Campos Tecnológico e Nuclear) for their information on XRD data files. This research was financially supported by the Fundação para a Ciência e Tecnologia (SFRH/BDE/51439/2011 and ID/MULTI/00612/2013).

REFERENCES

[1] R. Hughes and M. Rowe, The colouring, bronzing and patination of metals, a manual for the fine metal worker and sculptor, The Crafts Council, London, United Kingdom, (1982), ISBN 0-903789-60-3. [ Links ]

[2] J. Rudoe (Oxidized silver in the 19 th century: the documentary evidence), in Metal Plating and Patination. Cultural, technical & historical developments. (S. La Niece & P. Craddock, eds.), Butterworth-Heinemann, Oxford, United Kingdom, pp.161-170 (1993). [ Links ]

[3] S. La Niece, V. Harris and H. Uchida, ISIJ Int., 5, 1111-1116 (2014). [ Links ]

[4] R. Murakami (Japanese Traditional Alloys), in Metal Plating and Patination. Cultural, technical & historical developments. (S. La Niece & P. Craddock, eds.), Butterworth-Heinemann, Oxford, United Kingdom, pp.85-94 (1993). [ Links ]

[5] S. Barten (Materials and Techniques in the Jewelry of René Lalique) in The Jewels of Lalique. (Yvonne Brunhammer ed.), Flammarion, New York, USA, p. 120-140 (1998). [ Links ]

[6] C. W. Corti (Blue, black and purple! The special colours of gold) in The Santa Fe Symposium on Jewelry Manufacturing Technology (Eddie Bell, ed.), Albuquerque, USA, p.121 (2004). [ Links ]

[7] L. Fitzgerald (Structured questions- Question number 5: How do artificially produced corrosion products differs from naturally formed corrosion products, if at all?) in Proceedings of a Seminar Corrosion and Metal Arfacts - A dialogue between Conservators and Archaeologists and Corrosion Sciensts, March, Gaithersburg Maryland, USA, p.208-211 (1977). [ Links ]

[8] I. Tissot (Para além da superfície - A conservação de metais nas artes decorativas) in Proceedings of VI Jornadas de Arte e Ciência, Universidade Católica Portuguesa, February, Porto, Portugal, p. 74-86 (2010). [ Links ]

[9] I. Tissot, O. C. Monteiro, M. A. Barreiros, V. Corregidor, J. Correia and M. F. Guerra, RSC Adv., 6, 51856-51863 (2016). [ Links ]

[10] S. Praharaj, S. Nath, S. Panigrahi, S. Basu, S. K. Ghosh, S. Pande, S. Jana and T. Pal, Chem. Commun., 36, 3836-3838 (2006). [ Links ]

[11] M. Jafari, A. Sobhani and M. Salavati-Niasari, J. Ind. Eng. Chem., 20, 3775-3779 (2014). [ Links ]

[12] S.-Y. Zhang, C.-X. Fang, W. Wei, B.-K. Jim, Y.-P. Tian, Y.-H. Shen, J.-X. Yang and H.-W. Gao, J. Phys. Chem. C., 111, 4168-4174 (2007). [ Links ]

[13] M. Grimwade (Working, Annealing and Deformation Processes) in The Santa Fe Symposium on Jewelry Manufacturing Technology. (Eddie Bell, ed.), Albuquerque, USA, p.63-98 (2003). [ Links ]

[14] J. Fischer-Bühner (Improvement of Sterling Silver Investment Casting) in The Santa Fe Symposium on Jewelry Manufacturing Technology. (Eddie Bell, ed.), Albuquerque, USA, p.217-249 (2006). [ Links ]

[15] M. Ye, X. Wen, N. Zhang, W. Guo, X. Liu and C. Lin, J. Mater. Chem. A, 3, 9595-9600 (2015). [ Links ]

[16] J. Xu, X. Yang, T.-L. Wong and C.-S. Lee, Nanoscale, 4, 6537-6542 (2012). [ Links ]

[17] T. Ungár, Adv. Eng. Mater., 5, 323-329 (2003). [ Links ]

Notas

1 Shakudo is a black patinated copper-gold alloy with a percentage of gold that varies between 4 and 7% [3]. The patina is obtained by the application of nikomi-chakushoku, a traditional colouring treatment used in Japan in which the metal is polished to a mirror finish and then boiled in an aqueous solution containing copper carbonate, copper sulphate and potassium aluminium sulphate [4].

2 Shibuichi is a grey patinated copper-silver alloy [3]. The grey patina is obtained by using nikomi-chakushoku [4].