Serviços Personalizados

Journal

Artigo

Indicadores

Links relacionados

Compartilhar

Revista de Ciências Agrárias

versão impressa ISSN 0871-018X

Rev. de Ciências Agrárias vol.40 no.4 Lisboa set. 2017

https://doi.org/10.19084/RCA17116

ARTIGO

Influence of ripening stages on physicochemical characteristics of acerola fruits

Influência dos estádios de maturação nas características físico-químicas de frutos de acerola

Carla V. Corrêa1, Aline M. de S. Gouveia1, Bruno N. M. Martins1*, Letícia G. Jorge3, Natália de B. L. Lanna1, Ana Emília B. Tavares1, Veridiana Z. Mendonça2 and Regina M. Evangelista1

1Universidade Estadual Paulista (UNESP), Departamento de Horticultura, Botucatu-SP, Brasil, CEP: 18610 – 307

2 Universidade Estadual Paulista (UNESP), Departamento de Energia na Agricultura, Botucatu-SP, Brasil, CEP: 18610 – 307

3 Universidade Estadual Paulista (UNESP), Departamento de Botânica, Botucatu-SP, Brasil.

(*E-mail: brunonovaes17@hotmail.com)

ABSTRACT

The current study aimed to evaluate the influence of six ripening stages on physicochemical characteristics of acerola fruits from cultivar Olivier. The fruits were obtained at Experimental Orchard of the Sao Paulo State University. The experimental design was completely randomized, with six ripening staged and four replications. The physicochemical characteristics evaluated were pH, soluble solids, titratable acidity, ratio, ascorbic acid (vitamin C), reducing sugars, total sugars, sucrose and colour. There was a decrease in the levels of ascorbic acid and total sugars at full ripeness. However, the levels of sucrose increased during ripening. With regards to the ascorbic acid, there were significant differences for all six maturity stages, by the time the peel colour was quite red, meaning its fully ripened stage, it presented 1675.67 mg/100 g of fresh weight, hence lower than fully green (3175.67 mg/100 g of fresh weight).

Keywords: Malpighia glabra L., postharvest, vitamin C, sugars.

RESUMO

O objetivo do trabalho foi avaliar o efeito de seis estádios de maturação nas características físico-químicas da acerola cultivar Olivier. Os frutos foram obtidos de plantas presentes no pomar experimental da Fazenda Experimental da Universidade Estadual Júlio de Mesquita Filho. O delineamento experimental utilizado foi inteiramente casualizado, com seis pontos de maturação e quatro repetições. As características avaliadas foram: pH, sólidos solúveis, acidez titulável, ratio, ácido ascórbico (vitamina C), açúcares redutores, açúcares totais, sacarose e cor. Foi observada redução do ácido ascórbico e dos açúcares totais com a maturação total dos frutos. Para a sacarose houve aumento em seus teores com a maturação dos frutos. Em relação ao ácido ascórbico, verificou-se menores concentrações em frutos totalmente maduros (1675.67 mg/100 g de massa fresca) quando comparados aos frutos totalmente verdes com média de 3175.67 mg/100 g de massa fresca.

Palavras-chave: Malpighia glabra L., pós-colheita, vitamina C, açúcares.

INTRODUCTION

Acerola cherry or the West Indian cherry tree (Malpighia glabra L.) is a tropical plant. It is native to Central America, though it was spread to South America due to its adaptability Silva et al. (2016). Acerola presents high vitamin C content, but also other nutrients, such as vitamin A; B-complex vitamins (thiamine, riboflavin and niacin); iron; calcium; and carotenoids (Seeram, 2008; Bortolotti et al., 2013).

Growing acerola is quite common in several countries, as it plays an important role in healthy diet, being consumed either natural or manufactured (Duzzioni et al., 2013). The fruit ripening stage and senescence rapidly occur; consequently, reducing the storage period and commercialization. This process is due to the intense respiratory activity, because acerola is classified as a climacteric fruit; therefore, fruits undergo changes in peel colour; firmness loss; scent and flavour development during ripening stage (Reinhardt and Oliveira, 2003).

Market destination plays a crucial factor for growing acerola (Alves et al., 1995; Oliveira et al., 1999), i.e. fresh fruit markets or industry, e.g. frozen form and juice/pulp production. Thus, acerola fruits must be harvested when presenting an intense red colour (mature), but still firm to withstand transport and handling. If ripe fruits were not frozen, they should be immediately consumed, as it becomes unfit for consumption after 24 hours (Soares Filho and Oliveira, 2003). When acerola fruits are destined for distant markets, fruits should be harvested at semi-mature or mature stage; or at the beginning of ripening; or when there is a change in the fruit peel colour. At these stages, fruits are rich in vitamin C and more resistant to handling; consequently, increasing shelf life to 3-4 days. However, a lower pulp yield is obtained when compared to fully mature fruits (Santos et al., 1999). Although, it is recommended that green fruits should be commercialized into powder form; lyophilized; ultra filtrates; capsules and concentrates that enriches meals, since vitamin C is of utmost importance and generally high at this stage (Soares Filho and Oliveira, 2003).

Thus, the physiochemical changes that acerola fruits undergo throughout ripening stage, allows choosing the period that performs the highest yields according to the market demand. Therefore, the current study aimed to assess the physicochemical properties of acerola fruits at six maturity stages.

MATERIAL AND METHODS

The experiment was conducted at Sao Manuel Experimental Farm, Botucatu School of Agronomy, UNESP (22°46'S, 48°34'W; 740 m altitude). According to Köppen classification, the climate is Cwa (warm temperate and humid). The mean temperature of the warmest month is above 22°C; and the coldest is 17.5°C (Cunha and Martins, 2009). The mean annual rainfall is 1445 mm. The soil is classified as Dystrophic Red Latosol (Oxisoil).

The experimental design was randomized complete block, with six maturity stages and four replications; being used the cultivar Olivier, in plants of ten years. Fruits were randomly harvested and packed into plastic bags to avoid mechanical damages. The fruits were harvest in same day and separated per peels colours. Afterwards, they were transported to the Postharvest Fruits Laboratory in the Horticulture Department, Botucatu School of Agronomy - UNESP. Then, fruits were washed with tap water; dried at room temperature; and separated into six treatments according to the maturity stages, with four replications and 20 fruits per repetition. The treatments were: 1 - 100% green peel colour; 2 - 80% green peel colour with yellowish traces; 3 - 70% green peel colour with red lines; 4 - 60% yellow peel colour with red traces; 5 - 75 red peel colour with yellow traces; and 6 - 100% red peel colour.

Moreover, fruits were analysed for pH, soluble solids, titratable acidity, ascorbic acid and reducing sugars, total reducing sugars, sucrose and peel colour. Titratable acidity was determined by titrating 1 g of homogenized pulp in 100 ml of distilled water against freshly prepared 0.1 N sodium hydroxide expressed as mg Citric acid 100 g-1of acerola pulp by using 1 per cent phenolphthalein as indicator, according to Institute Adolfo Lutz (Brasil, 2005). Soluble solids (SS/ Brixº) were determined by placing two drops of macerated juice for one minute on the prism surface of electronic refractometer (Atago, PR32 model), according to Association of Official Analytical Chemistry (2005). The pH was directly determined on samples using a potentiometer (Digital DMPH-2), according to the methodology described by Adolfo Lutz Institute, Brasil (2005). The levels of reducing sugars were determined by the method described by Somogyi and adapted by Nelson (1944), the results are expressed in mg per g. Ascorbic acid content was determined by titrating 2.6 dichlorophenolindophenol, according to the methodology described by MAPA (2001) and results are expressed as mg 100 g of fresh weight. The peel colour was determined by using a colorimeter (Konica Minolta CR-400), readings were: L* (lightness) representing the surface brightness (L* = 0 - black and L* = 100 - White); C* (chroma, colour intensity); hue - Hº (colour angle with 360oC rotation) with 0°, 90°, 180° and 360°, i.e. representing red, yellow, green and blue, respectively (Ding et al., 2007). The results were submitted to Tukey test at 5% probability by Sisvar statistical software.

RESULTS AND DISCUSSION

Regarding to the pH, there was some difference, whereas the lowest value (3.48) was found in treatment 2 (i.e. green fruit); and the highest value (3.58) was observed in treatment 6 (fully ripened fruit) (Table 1). During the ripening process, pH increased when acidity decreased. The same pattern was observed by Adriano et al. (2011), who found higher pH value in fully ripened than semi-mature fruits; but it does the opposite to titratable acidity.

Oliveira et al. (1999) obtained pH from 2.50 to 3.30 with frozen acerola pulp, i.e. lower than the current study. However, Mercali et al. (2011), observed values of 3.28. These differences are expected, as physical and chemical characteristics may vary from each cultivar; maturity stage; soil; weather condition; and management practice (Folegatti and Matsuura, 2003).

For titratable acidity, it was obtained higher values in 100% green fruits (treatment 1), with an average of 0.80%. On the other hand, in 100% fully ripened fruits (treatment 6) the acidity values were lower, with an average of 0.69% (Table 1). It is common to observe an increase in acidity during fruit ripening due to the accumulation of organic acids. This result is due to the fact that there is a reduction in the malate oxidase activity, resulting in the accumulation of malic acid (Ferreira et al., 2009). Yet many organic acids are used as substrates for respiratory activity during ripening; consequently, reducing titratable acidity, as occurred in the current study. Thus, the decrease in titratable acidity may be related to the reduction of ascorbic acid in almost 50% of unripe fruits to fully ripened ones. In addition, this species presented a high level of ascorbic acid; therefore, favouring acidity reduction, in other words, increasing pH (Vendramini and Trugo, 2000). The values of titratable acidity were close to those reported by Oliveira et al. (1999), while acerola pulp ranged from 0.47 to 1.56 % in citric acid.

No difference was observed for soluble solids content, with an average of 6.53°Brix (Table 1). This content was in agreement with those reported by Vendramini and Trugo (2004), when evaluated the characteristics of ripened fruits of acerola (9.2° Brix). But Oliveira et al. (1999), presented values from 4.40 to 9.16° Brix for soluble solids in acerola pulp.

At ripening, there was an increase in the ratio, with a maximum value of 10.73 (treatment 6), i.e. fully ripened fruits in July. Ratio is an important quality attribute for acerola fruits, as it assesses flavour and selects raw material for processing. Thus, this association tends to increase during ripening. The same pattern was observed by Adriano et al. (2011), but presenting lower values, such as 2.41 for ripened fruits.

With regards to the ascorbic acid, there were significant differences for all six maturity stages, by the time the peel colour was quite red, meaning its fully ripened stage, it presented 1675.67 mg/100 g of fresh weight, hence lower than fully green (3175.67 mg/100 g of fresh weight) (Table 1). In other words, the more the ripening stage, the lesser the ascorbic acid content, i.e. ascorbic acid content was higher in 100% green peel colour. This feature was also observed by other authors such as Santos et al. (1999). According to Butt (1980), this occurs because an enzyme activity called oxidase ascorbic acid (ascorbate oxidase) presents higher activity in full ripen fruits than unripe fruits; therefore, explaining some of the losses found during ripening. According to Nogueira et al. (2002), unripe fruits exhibit ascorbic acid levels significantly higher than mature fruit and semi-mature; consequently, being used by the pharmaceutical industry. In the current study, the ascorbic acid levels (1675.67 mg/100 g of fresh weight) in fully ripened fruits were higher than those recommended by FAO/WHO (2001), i.e. 45 mg per day.

For the reducing sugars, there was no significant difference, averaging 3.95 mg per g ( Table 2), similar to those observed by Oliveira et al. (1999) ranged from 2.05 to 4.95%; by Asenjo and Moscoso (1950), with an average from 2.8 to 3.7 g/100 ml; by Santini (1953), with an average between 3.7-3.9 g/100 ml; and by Diogenes Nogueira (1991), who obtained an average from 2.84 to 3.94%. However, these averages were lower than those found by Nunes (1996) for natural pulp, i.e. 5.50 and 5.10%.

Regarding to the total reducing sugars, it was observed a decrease during fruit ripening, being the lowest content (0.66 mg per g) observed during full ripening. In general, the sugar content increases in fruit ripening by biosynthetic process. In plant organs, starch is the main carbohydrate storage. Therefore, storage hydrolysis occurs during ripening; as a result there is glucose, oxidized by cellular respiration. Oxidative process is the means by which living cells use their reserves, as a carbon source, resulting in the production of energy and new organic compounds.

This behavior is different to those observed by Ferreira et al. (2009), while evaluating acerola fruits at the best harvest point for industry, observed an increase in total reducing sugars content during ripening, with values ranging from 7.57% (greener fruits) to 12.43% (full ripening). Probably this difference should be related to the fruit sugar content being an intrinsic factor, such as genotype, environment and management practice. Moreover, it plays an important role in food industry, e.g. juice production, because it allows a better processing performance (Ferreira et al., 2009).

Sucrose increased during ripening stage, ranging from 1.87 mg per g (totally unripe) to 3.06 mg per g (fully ripened fruits) (Table 2). As the starch is being hydrolyzed during ripening, there is an increase in sucrose levels that act as an energy reservoir (Taiz and Zeiger, 2004).

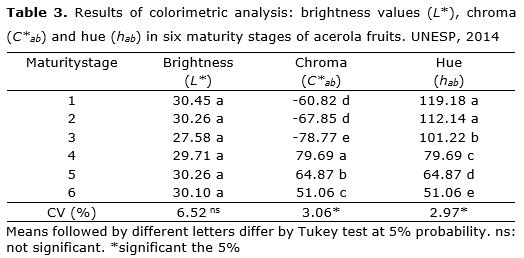

No difference was observed for brightness at the six maturity stages, averaging 29.72. These results are contradictory from Vendramini and Trugo (2000), when evaluated the chemical composition of acerola at three maturity stages, observed that the brightness of the fruit increased when changed from immature fruit to intermediate maturity; However, luminosity decreased with increasing age. Thus, fruit colours are the result from not only the pigments processed on the surface, but also complex biochemical changes during fruit ripening, which in turn may vary from each genotype (Kramer, 1973).

For chroma, semi-ripe fruits or 60% yellow peel colour with red lines showed the highest values. The greatest value of chroma indicates that these fruits showed more vivid colours than full ripening; consequently, it is observed that red peel (100%) loses more vivid coloration due to the onset of pigment degradation by the fruit deterioration.

With regards to hue (tonal value), the highest values were obtained for green fruit with hue of 119.18, while 51.06 for fully ripened fruits (reddish colour); in other words, when becomes dark, a decrease in hue is observed (Table 3). The colour data confirm the difference in the maturity stage between treatments. However, these values were higher than those found by Adriano et al. (2011) who found values of 39.81 or semi-ripe fruit (orange colour), while 30.08 for ripe fruit (reddish).

CONCLUSIONS

Therefore, the current study presented the psychochemical changes that occurred during ripening of acerola fruits; besides that the characterization of the fruits at different maturity stages is of utmost importance to define specific stages, according to the market destination.

Ascorbic acid is the main component of acerola and of great interest to the industry. The better the ascorbic acid content, i.e. ascorbic acid content was higher in 100% green peel colour.

Furthermore, it is recommended that green fruits are picked, as there is a high loss during ripening.

References

Adriano, E.; Leonel, S.& Evangelista, R.M. (2011) - Qualidade de fruto da aceroleira cv. Olivier em dois estádios de maturação. Revista Brasileira de Fruticultura, vol. 33, p. 541-545. http://dx.doi.org/10.1590/S0100-29452011000500073 [ Links ]

Alves, R.E.; Menezes, J.B. &Silva, S.M. (1995) - Colheita e pós-colheita da acerola. In: São José, A. R., Alves, R.E. (Eds.) - Acerola no Brasil: produção e mercado. Vitória da Conquista, UESB, p. 77-89. [ Links ]

Asenjo, C.F. & Moscoso, C.G. (1950) - Ascorbic and content of the west Indian Cherry. Food Research, vol. 15, p. 103-106. [ Links ]

Association Official Analytical Chemistry. (2005) -Official methods of analysis of the association of oficial analytical chemistry. 18 ed. Gaithersburg, 1015 p. [ Links ]

Bortolotti, C.T; Santos, K.G.; Francisquetti, M.C.C.; Duarte, C.R. & Barrozo, M.A.S. (2013) - Hydrodynamic study of a mixture of West Indian cherry residue and soybean grains in a spouted bed. The Canadian Journal of Chemical Engineering, vol. 91, n. 11, p. 1871–1880. http://dx.doi.org/10.1002/cjce.21870 [ Links ]

Brasil. (2005) - Ministério da Saúde Agência Nacional de Vigilância Sanitária. Métodos físico-químicos para análise de alimentos. Brasília, Ministério da Saúde, 1018 p.

Butt, V.S. (1980) - Direct oxidases and related enzymes. In: Stumpf, P.K. & Conn, E.E. (Eds.) - The biochemistry of plants: a comprehensive treatise, New York, Academic, p. 81-123. [ Links ]

Cunha, A.R. & Martins, D. (2009) - Classificação climática para os municípios de Botucatu e São Manuel, SP. Irriga, vol. 14, n. 1, p. 1-11. http://dx.doi.org/10.15809/irriga.2009v14n1p01 [ Links ]

Ding, P.; Ahmad, S.H. & Ghazali, H.M. (2007) - Changes in select quality characteristics of minimally processed carambola (Averrhoa carambola L.) when treated with ascorbic acid. Journal of the Science of Food and Agriculture, vol. 87, n. 4, p. 702-709. http://dx.doi.org/10.1002/jsfa.2772 [ Links ]

Diogenes Nogueira, C.M.C.C. (1991) - Estudo químico e tecnológico da acerola (Malpighia glabra). Dissertação de Mestrado. Fortaleza, Universidade Federal do Ceará. 119 p. [ Links ]

Duzzioni, A.G.; Lenton, V.M.; Silva, D.I.S. & Barrozo, M.A.S. (2013) - Effect of drying kinetics on main bioactive compounds and antioxidant activity of acerola (Malpighia emarginata D.C.) residue. International Journal of Food Science e Technology, vol. 48, n. 5, p. 1041–1047. http://dx.doi.org/10.1111/ijfs.12060 [ Links ]

FAO/WHO. (2001) - Human Vitamin and Mineral Requirements. Bangkok, Joint FAO/OMS Expert Consultation, 286 p. [ Links ]

Ferreira, R.M.A; Aroucha, E.M.M.; Souza, P.A.A.; Queiroz, R.F. & Pontes Filho, F.S.T. (2009) - Ponto de colheita da acerola visando à produção industrial de polpa. Revista Verde, vol. 4, n. 2, p. 13–16. [ Links ]

Folegatti, M.I.S. & Matsuura, F.C.U. (2003) - Produtos. In: Ritzinger, R.; Kobayashi, A.K.; Oliveira, J.R.P. (Eds.) - A Cultura da Aceroleira. Cruz das Almas, Embrapa Mandioca e Fruticultura Cruz das Almas, p. 198. [ Links ]

Kramer, A. (1973) - Fruits and vegetables. In: Kramer, A. & Twigg, B.A. (Eds.) - Quality control for the food industry, Westport, Avi, p 157- 227. [ Links ]

MAPA. (2001) - Métodos do Ministério da Agricultura para Análise de Bebidas. Ministério da Agricultura, Pecuária e Abastecimento. [cit. 2014-11-03]. < http://www.bevtech.com.br/infotec/> [ Links ]

Mercali, G.D.; Sarkis, J.L.; Jaeschke, D.P.; Tessaro, I.C. & Marczak, L.D.F. (2011) – Physical properties of acerola and blue berry pulps. Journal of Food Engineering, vol. 106, n. 4, p. 283–289. https://doi.org/10.1016/j.jfoodeng.2011.05.010 [ Links ]

Nelson, N.A. (1944) - A photometric adaptation of somogy method for the determination of glucose. Journal Biological Chemical, vol. 153, p. 375-380. [ Links ]

Nogueira, R.J.M.C.; Moraes, J.A.P.V.; Burity, H.A. & Silva Junior, J.F. (2002) - Efeito do estádio de maturação dos frutos nas características físico-químicas da acerola. Pesquisa Agropecuária Brasileira, vol. 37, n. 4, p. 463-470. http://dx.doi.org/10.1590/S0100-204X2002000400006 [ Links ]

Nunes, R.G.F.L. (1996) - Estudo do perfil de aminoácidos livres em acerola (Malpighia emarginata D.C.). Dissertação de Mestrado. Fortaleza, Universidade Federal do Ceará. 84 p. [ Links ]

Oliveira, M.E.B.; Bastos, M.S.R.; Feitosa, T.; Branco, M.A.A.C. & Silva, M.G.G. (1999) - Avaliação de parâmetros de qualidade físico-químico de polpas congeladas de acerola, cajá e caju. Ciência e Tecnologia de Alimentos, vol.19, n. 3, p. 326-332. [ Links ]

Reinhardt, D.H. & Oliveira, J.R.P. (2003) - Manejo pós-colheita. In: Ritzinger, R.; Kobayashi, A.K. & Oliveira, J.R.P. (Eds.) - A cultura da aceroleira. Cruz das Almas, EMBRAPA, p. 150-163. [ Links ]

Santini, J.R. (1953) - Determination of reducing and total sugars in west Indian Cherry (Malpighia punicifolia L.) juice. The Journal of Agriculture of the University of Puerto Rico, vol. 37, p. 199-205. [ Links ]

Santos, A.R.L. Reinhardt, D.H.; Silveira, W.R.; Oliveira, J.R.P. &Caldas, R.C. (1999) - Qualidade pós colheita de acerola para processamento, em função de estádios de maturação e condições de armazenamento. Revista Brasileira de Fruticultura, vol. 21, n. 3, p. 365-371. [ Links ]

Seeram, N.P. (2008) - Berry fruits: compositional elements, biochemical activities, and the impact of their intake on human health, performance, and disease. Journal of Agricultural and Food Chemistry, vol. 56, n. 3, p. 627-629. http://dx.doi.org/10.1021/jf071988k [ Links ]

Silva, P.B.; Duarte, C.R. & Barrozo, M.A.S. (2016) - Dehydration of acerola (Malpighia emarginata D.C.) residue in a new designed rotary dryer: Effect of process variables on main bioactive compounds. Food and Bioproducts Processing, vol. 98, p. 62-70. http://dx.doi.org/10.1016/j.fbp.2015.12.008 [ Links ]

Soares Filho, W.S. & Oliveira, J.R.P. (2003) - Colheita. In: Ritzinger, R.; Kobayashi, A.K. & Oliveira, J.R.P. (Eds.) - A cultura da aceroleira. Cruz das Almas, EMBRAPA, p. 145-149. [ Links ]

Taiz, L. & Zeiger, E. (2004) - Fisiologia vegetal. 3aed. Porto Alegre, Artmed, 565 p. [ Links ]

Vendramini, A.L. & Trugo, L.C. (2000) - Chemical composition of acerola fruit (Malpighia punicifolia L.) at three stages of maturity. Food Chemistry, vol. 71, n. 2, p. 195-198. https://doi.org/10.1016/S0308-8146(00)00152-7 [ Links ]

Vendramini, A.L. & Trugo, L.C. (2004) - Phenolic compounds in acerola fruit (Malpighia punicifolia L.). Journal of the Brazilian Chemical Society, vol. 15, n. 5, p. 664-668. http://dx.doi.org/10.1590/S0103-50532004000500009 [ Links ]

Received/recebido: 2017.05.08

Received in revised form/recebido em versão revista: 2017.07.21

Accepted/aceite: 2017.07.21