Introduction

All-ceramic systems show a potential to equal the optical properties of natural teeth.1 Core translucency has been identified as one of the most important factors in controlling the restoration esthetics, being decisive in material selection.2

Contrary to the completely opaque metal-ceramic infrastructures, most ceramic core materials present some intrinsic translucency and can interact with the substrate after cementation.

This feature could be an advantage but also a problem for the restoration’s final esthetic result.

Most zirconia core materials, called Y-TZP, have a polycrystalline base stabilized at the tetragonal phase by yttrium.3 Despite being commercialized under the same name, comercial zirconia materials have slight differences in composition and microstructure.4 As a result, they can present different opacity and be less translucent than alumina.5,6 Most zirconia materials can be used to camouflage the dark color of preparations or post cores.7 More-translucent zirconia materials have recently become available aimed to improve restoration color properties, but their impact and interaction with the background have not yet been studied.

CAD-CAM technology allowed developments in ceramic high-strength materials producing alumina and zirconia infrastructures. Studies have advocated covering these materials with more-translucent ceramics to reach a higher esthetic outcome comparable to natural teeth.2,8,9 This procedure with NobelProcera alumina high-strength cores provided optimal results.10

The literature has suggested other methods to obtain better esthetic results, such as coloring white zirconia by infiltration of rare oxide solutions,11 using pre-colored zirconia blocks, using ceramic “liner” materials,12 reducing the thickness of the cores,7 controlling zirconia grain size,13 and using diferente ceramic recovering techniques.8,14,15 With the development of zirconia core materials with different compositions, fabrication procedures, and coloring techniques, it is mandatory to determine their influence on the translucency and final color of the restorations.16 The translucency and color of ceramic restorations depend on core and veneering characteristics17 and have been highly correlated.7

Translucency occurs when light passes through the material and is partially scattered, transmitted (transmittance), or reflected. The more light passes through, the more translucency occurs. This phenomenon is inversely related to the material layers’ thickness since its increase provokes more absorption (Lambert-Beer law), less transmission, and a higher scattering effect.18 Scattering is a characteristic of zirconia and alumina cores due to their high crystalline content. However, alumina still presents a high translucency when compared to zirconia,17 despite the current manipulation of zirconia under higher temperatures and longer cycles to achieve better translucency.13

The color of ceramic restorations layered with diferente ceramics and layer combinations depends on the core material, even when its thickness is standardized to 1.5 mm.2 In a ceramic restoration, the more translucent the core, the better the revelation of the tooth layers’ inner color. Due to being less translucent, zirconia and alumina hinder natural color achievement but camouflage better the dark colors of any preparations.1

One study analyzed the influence of the background on the color of zirconia-core restorations with a final thickness of 1.5 mm, and revealed no statistical differences between metal and composite substrates but found color differences (ΔE) of 1.2-3.1 between the two, which may affect restoration color perception.19 The most used clinically acceptable threshold for ΔE is 3.7. However, for a color match between a natural tooth and an all-ceramic restoration, in vivo tests have detected mean values of ΔE*ab=1.6.14,20 Based on a recently published review,21 more than half of 37 referenced articles used ΔE=1 as the perceptibility threshold, the second most used value was ΔE*ab=1.6, and only 1/3 of the studies used the clinically acceptable threshold of ΔE=3.7.21

This study aimed to investigate the transmittance (%T) and color difference (ΔE*) of seven high-strength ceramic core materials over eight colored substrates before and after ceramic application. The following null hypotheses were established: (H01) there are no differences between the %T of the various high-strength ceramic core materials; (H02) there are no diferences between the ΔE* of the various high-strength ceramic core materials; and (H03) the substrate does not affect the ΔE* of the various high-strength ceramic core materials.

Material and methods

Disk-shaped specimens with a 12-mm diameter and a 0.4±0.01-mm thickness were fabricated using CAD/CAM processes.9 The specimens’ diameter was selected to fit a metallic calibration device (Porcelain Sampler, Smile Design, Switzerland) used to ensure the approximated thickness of ceramic layers applied over the cores and to fit the samples to the color measuring devices.

NobelProcera alumina (Nobel Biocare AB, Stockholm, Sweden) and white and colored NobelProcera zirconia (medium) specimens were produced by the manufacturer to final thickness and later modified to eliminate a side edge that ensured the production of dry-pressed flat surface specimens. The side edge was removed using a sintered diamond bur (Sintered Diamond 5022 HP, Edenta, Switzerland) at 25.000 rpm, a ceramic disk (Cera Pro 3.0 mm, Edenta, Switzerland), and a polishing disk (Meister Point SF-41, Noritake, Japan) at 15.000 rpm to fit the specimens to a metallic sampler (Porcelain Sampler Ref. 7015, Smile Line, Switzerland) used to apply ceramic over specimens.

Zirkonzahn Ice Translucent (Zirkonzahn, Brunico, Italy) and Zirkonzahn Prettau zirconia specimens were first obtained by wet slicing, on a precision saw (Isomet 1000 - Buehler), 0.5±0.01 mm slices from cylinders (18-mm high and 14.4-mm diameter) draw and cut from disk-shaped blocks (Ice Translucent zirconia, Ref: ZRAB8041- Lot: ZB2211G; Prettau zirconia Ref: ZRAD8041-Lot: ZB2112C) on the Zirkonzahn 5-TEC system. Colored Zirkonzahn specimens were obtained by infiltrating the white disks on a manufacturer’s acid solution (VITA D3 color) before sintering. Sintering of white and colored specimens was made at 1500°C for Ice Translucent zirconia and 1600°C for Prettau zirconia, both with a heating rate of 8°C/min and a hold time of 120 min, to a final thickness of 0.4 mm.

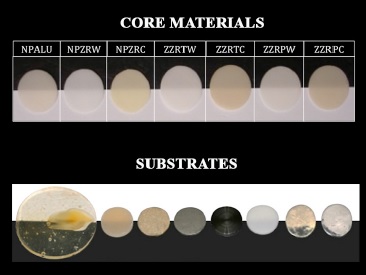

Based on pilot study data, the sample size (n=5) was estimated with a power analysis to provide a statistical significance (α=0.05) at a power of 80%.22 A total of seven groups were established: NobelProcera alumina (NPALU), white NobelProcera zirconia (NPZRW), colored NobelProcera zirconia médium (NPZRC), white Zirkonzahn Ice Translucent zirconia (ZZRTW), white Zirkonzahn Prettau zirconia (ZZRPW), colored Zirkonzahn Ice Translucent zirconia (ZZRTC), and colored Zirkonzahn Prettau zirconia (ZZRPC) (Figure 1). Specimens were measured using a digital micrometer (Mitutoyo Manufacturing Company Ltd, Kawasaki, Japan) to ensure thickness and cleaned with a steam jet (VK300, Ivoclar Vivadent AG, Liechtenstein) prior to spectrophotometer readings.

%T was quantitatively determined by direct light transmission in the visible light spectrum (380 nm to 800 nm) using a Helios Alpha spectrophotometer (Thermo Electron Corporation, USA). Specimens were mounted in a custom-made opaque black acrylic support to seal edges and ensure light penetration through the specimen in a centered 0.7-mm-diameter medium area.

ΔE* was measured with a VITA Easyshade Compact spectrophotometer (VITA Zahnfabrik, Germany),9,23 against eight different backgrounds, representing usual core materials in teeth or implant restoration: dentin, composite, polished and sandblasted yellow gold alloy, polished and sandblasted Co-Cr alloy, titanium, and zirconia (Figure 1). The equipment captured color coordinates using a D65 illuminant and a 2-degree viewing angle. The spectrophotometer probe was placed over the center of the specimen using the same custom-made device used to measure direct light transmission to ensure correct and consistent positioning. Glycerol (C3H8O3), with a 1.48 refraction index, was used as a medium to promote good contact between the specimen and the background. The instrument was recalibrated after every five measurements. The CIE ΔE* value was recorded as the numerical distance between the L*C*h* coordinates of the sample and the color target (D3 VITAPAN, VITA Zahnfabrik, Germany).23 A clinically acceptable threshold of 3.7 ΔE units was used as a reference.

After measuring the initial core %T and color, specimens were veneered with Nobel Rondo ceramic. Alumina specimens were veneered with Base Liner ceramic Pearl Chroma (Wieland NR; Ref: 31799, Lot: 0104, Germany), and zirconia specimens with the correspondent material (Wieland NR; Ref: 32455, Lot: 0308, Germany). Base Liner ceramic was mixed using Liner Liquid (Wieland NR; Lot: 3008, Germany) and applied to a uniform thickness using an instrument with a ceramic tip (Smile Line, Switzerland). Specimens were positioned over firing support (Smile Line, Switzerland) and fired in a vacuum furnace (Programat EP5000; Ivoclar, Lichtenstein) according to the manufacturer’s instructions (high temperature, 930°C; heat rate, 45°C/min for zirconia and 55°C/min for alumina; hold time, 1 min with vacuum). The thickness of the specimens was measured using a digital micrometer to ensure a 0.1 ± 0.05-mm thickness of liner ceramic. Specimens were steam-jet cleaned and placed inside a porcelain sampler (Porcelain sampler, Smile Line, Switzerland) set to 1.6-mm thickness. Nobel Rondo D3 dentin ceramic mixed with a soft liquid (Nobel Rondo, Wieland, Germany) was applied using a brush over specimens with the liner to the top of the sampler. The sampler was vibrated three times with appropriate instruments, and water was absorbed with paper tissues, to remove the excess liquid and guarantee the same condensation of ceramic over specimens. Alumina specimens were veneered with Pearl Chroma D3 dentin (Lot: 0208), and zirconia specimens with the corresponding material (Lot: 0508).

Dentin ceramic was sintered according to the manufacturer’s instructions (high temperature, 910°C; heat rate, 45°C/min for zirconia and 55°C/min for alumina; hold time, 1 min with vacuum). After sintering, specimens were measured in two perpendicular directions and ground on the dentin side on manual equipment (Lunn Major - Struers, Germany) with wet sandpaper (100 grit) to ensure a 1.4-mm thickness specimen with parallel flat surfaces. Finally, specimens were sandblasted with 50-μm Al2O3 at 2-bar pressure and steam jet.

The same procedure was used to apply Nobel Rondo E3 incisal ceramic. The porcelain sampler was set to ensure 0.2 mm of incisal ceramic after sintering. Alumina specimens were veneered with E3 incisal (Lot: 0204), and zirconia specimens with the corresponding material (Lot: 0409). Incisal ceramic was sintered according to the manufacturer’s instructions (high temperature, 900°C; heat rate, 45°C/min for zirconia and 55°C/min for alumina; hold time, 1 min with vacuum).

Specimens with a final thickness of 1.6 mm were glazed (Nobel Rondo - Lot: 308 and stain liquid) to the manufacturer’s instructions (high temperature, 880°C; heat rate, 45°C/min for zirconia and 55°C/min for alumina; hold time, 1 min with vacuum) and submitted to %T and color measurements according to the previously mentioned protocol.

%T mean values were calculated, and data were statistically analyzed using non-parametric Kruskal-Wallis tests followed by multiple comparisons using Mann-Whitney tests with Bonferroni correction (α=0.05). ΔE* data were statistically analyzed using Kruskal-Wallis tests followed by multiple comparisons to analyze the core material influence and repeated measurement tests (related-samples Friedman’s two-way ANOVA) to analyze the influence of the substrate (α=0.05).

Non-parametric Wilcoxon tests were used to analyze the %T of each core material before and after veneering (α=0.05).

Results

Because thickness is a co-variable related to %T, all specimens were measured prior to spectrophotometer readings to ensure similar thickness.

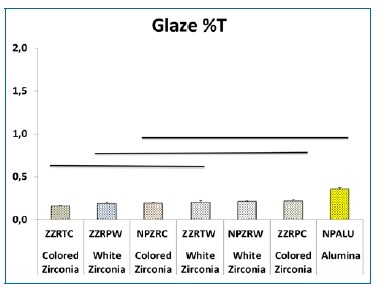

Statistically significant differences were found (p<0.001) in %T between core materials before and after veneering. %T was also significantly different (p<0.001) before and after ceramic application for all materials. Colored zirconia cores decreased %T equally (68%) after ceramic application, while ZZRPW (75%) was the most affected, surpassing NPALU (74%) (Table 1). Initially, the ZZRTC core material showed statistically significant differences to ZZRTW (p=0.035), ZZRPW (p=0.007), and NPALU (p=0.001). NPZRC was also statistically significantly less translucent than NPALU (p=0.002) (Figure 2). After glazing, the relation between core materials %T changed, with ZZRTC showing statistically significant differences to NPZRW (p=0.031), ZZRPC (p=0.016), and NPALU (p=0.001). ZZRPW was also statistically significantly less translucent than NPALU (p=0.025) (Figure 3).

Figure 2 %T of core materials at the initial stage. [Bars under the same horizontal line were not statistically different (p<0.05).]

Figure 3 %T of core materials at the glaze stage. [Bars under the same horizontal line were not statistically different (p<0.05).]

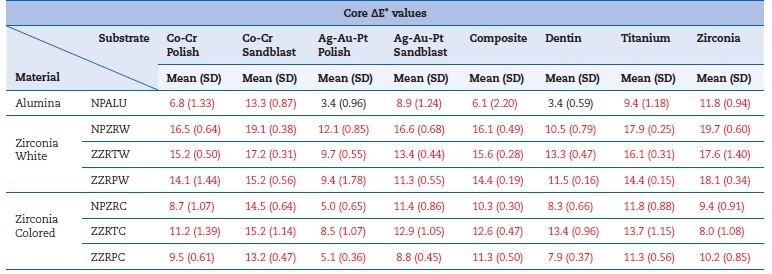

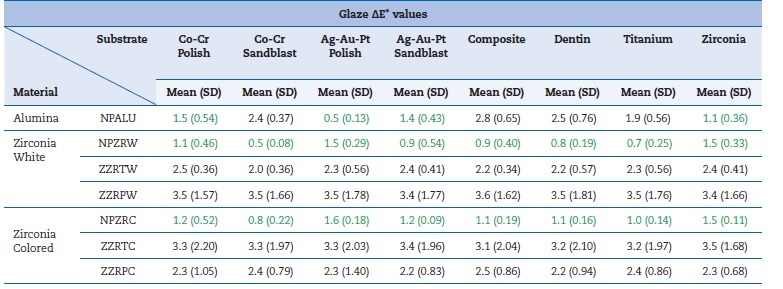

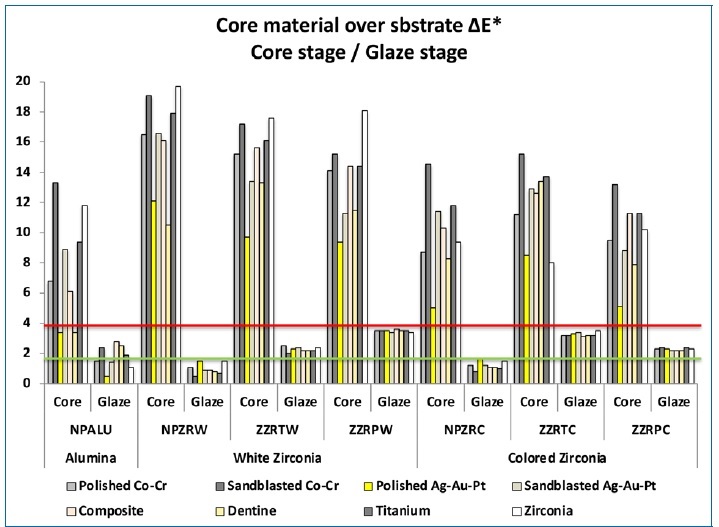

A statistically significant decrease in ΔE* was observed from the core (Table 2) to the glaze (Table 3) stages (p<0.001) for all substrates. The core material also influenced ΔE* (p<0.001) for all substrates in the two stages tested. Zirconia cores’ ΔE* values at the initial stage were all high above the clinically acceptable threshold (ΔE*<3.7) (Figure 4). Contrarily, alumina cores were closer to the threshold and even below it over dentine (ΔE*=3.4) and polished Ag-Au-Pt alloy (ΔE*=3.4) substrates. After the glaze stage, all core materials performed below the previously mentioned threshold. NPZRW had the best performance, with ΔE* values over all substrates below the clinical perceptibility threshold (ΔE*<1.6). In turn, NPZRC only exceeded it slightly over polished Ag-Au-Pt alloy, while NPALU registered values above the threshold for half of the substrates (dentin, composite, sandblasted Co-Cr alloy, and titanium). ZZRTW, ZZRPW, ZZRTC, and ZZRPC had ΔE* values between the two mentioned thresholds for all substrates.

Table 2 Color difference (ΔE*) values and standard deviation of each group over all the substrates at the core stage

Red values - ΔE*>3.7; Black values - ΔE*≤3.7; Green values - ΔE*≤1.6

Table 3 Color difference (ΔE*) values and standard deviation of each group over all the substrates at the glaze stage

Red values - ΔE*>3.7; Black values - ΔE*≤3.7; Green values - ΔE*≤1.6

Figure 4 Color differences (ΔE*) at two stages (the red line represents the clinically acceptable threshold; the green line represents the perceptibility threshold).

Core material multiple comparison tests after glaze showed no statistical differences (p>0.05) between NPZRW and ZZRPW over polished yellow gold alloy and zirconia substrates.

NPZRW and ZZRTC registered differences over dentin (p=0.044), sandblasted yellow gold alloy (p=0.029), and sandblasted Co-Cr alloy (p=0.027), while NPZRW and NPALU registered diferences over dentin (p=0.047) and sandblasted Co-Cr alloy (p=0.046).

NPZRC showed differences to ZZRPW over composite (p=0.044), sandblasted Co-Cr alloy (p=0.049), and titanium (p=0.044). NPALU registered differences to ZZRPW and ZZRTC over polished yellow gold alloy and zirconia substrates (p=0.003 and p=0.013 for the first and p=0.025 and p=0.005 for the latest, respectively). NPALU also registered a difference to ZZRTW over the zirconia substrate (p=0.044).

While the core stage showed a significant influence (p<0.001) of substrates on ΔE* values of core materials, after glaze, stage substrates only showed a highly significant influence (p<0.001)

under NPALU, NPZRW, and NPZRC core materials. Substrates did not influence ΔE* values under ZZRTW (p=0.051), ZZRTC (p=0.347), ZZRPW (p=0.611), and ZZRPC (p=0.972).

Discussion

Except for In-Ceram zirconia (Vitazahnfabrik, Germany), Y-TZP dental materials show some degree of translucency, even though transmittance is low in the visible spectrum range (< 2% for thickness greater than 0.4 mm),25 and are characterized as semi-translucent materials.9,24 There has been a tendency to change the zirconia materials’ composition to alter their translucency.26 However, even when optimized, zirconia translucency will typically be lower than alumina, spinel, or feldspathic ceramics.25

The present study’s results agree with previous studies,24 since all materials showed %T below 2%. Alumina showed more %T than all zirconia core materials, and Prettau zirconia was the most translucent among zirconia cores. Colored zirconia cores revealed less transmittance than white cores, as also mentioned in previous studies.7 However, statistically significant differences were only registered at the core stage between alumina (NPALU) and two colored zirconia cores (ZZRTC and NPZRC). These differences changed after the glaze stage when NPZRC was no longer statistically significantly diferente from NPALU, but ZZRPW was. This change in the behavior of white Prettau zirconia material between stages can be attributed to the specimens’ increased thickness since less translucent zirconia is less affected by this factor.26 Therefore, the null hypothesis H01 is rejected because transmittance diferences were observed at the two stages.

The exact composition of core materials used in the presente study is unknown because producers refused to give this information. However, the literature describes Prettau zirconia as a modification of the Ice Translucent zirconia, containing 0.25% more alumina.26 The Prettau zirconia specimens used were sintered at a temperature 100°C higher than Ice Translucent zirconia specimens and, thus, were expected to presente higher translucency than the other two white zirconia tested. Higher sintering temperatures and longer exposure to temperature also increase zirconia translucency.13

Studies have also justified differences between dental zirconia with differences in composition and molecular structure, namely the addition of alumina and the existence of a nano inter-granular structure of 10-100-nm alumina particles inside zirconia and 10-nm zirconia particles inside alumina grains. Other justifications have been the differences in sintering conditions, which can modify the material’s crystalline structure,7 and the influence of its refractive index and birrefringente nature on translucency.8

Because they are produced by outsourcing by the manufacturer, the compositions and sintering protocols of NPALU, NPZRW, and NPZRC have not been published yet. However, we can point out differences in the production and process conditions between materials from the two companies, as Nobel-Procera uses a dry/press processing system and obtains colored cores by coloring powder before processing, while Zirkonzahn uses soft machining and ads color by stain dying cores before sintering. The type of additives, sintering temperature, sintering atmosphere conditions, and temperature heat rate have already been mentioned as factors contributing to altering zirconia behavior after ceramic application.13,23,27

Another study28 pointed out the same factors to explain opacity differences found between Cercon (Dentsply, USA), Kavo Everest (Kavo, Germany), and NobelProcera (Nobel Biocare, Sweden) zirconia. It also mentioned a statistically significant difference in the mean contrast ratio between NobelProcera alumina and all the white zirconia tested, which was not found with the transmittance method.

The observed exact reduction in %T (68%) in all colored zirconia between the two stages indicates that pigmentation might act as a factor to eliminate the initial differences between zirconia core materials, as reductions among white zirconia were not the same after the glaze stage. The results suggest no different influences between zirconia cores’ color pigmentation techniques.

Dental support for restorations can be of various materials with different colors, over tooth or implants. Thus, it is importante to understand the interaction between restoration core materials, ceramic layering material, and dental substrates on color perception. This information can be crucial for material selection on esthetic rehabilitation. The present study observed significant ΔE* differences between the two stages tested. Applying 1.2 mm of ceramic over 0.4-mm alumina/zirconia cores reduced ΔE* values of all core materials, independently of the substrate used.

The null hypothesis H02 was rejected since ΔE* diferences among core materials were observed for both stages. Initially, colored cores showed lower ΔE* values than white cores, but, except for alumina over polished Ag-Au-Pt or dentine, they all performed above the clinically acceptable threshold (ΔE*>3.7),20 thus showing no inherent capacity to, at a thickness of 0.4 mm, camouflage the substrate color. These results agree with various studies using zirconia and other ceramic materials that also registered high ΔE* values and concluded that specimens with total thicknesses below 1.5 mm could not mask the substrate.9,23,29-34

This study also observed that the more translucent the colored core, the more significant the differences to the less translucent white cores. A relation between the material’s color and %T with the reduction of ΔE* over the different substrates was noticeable. However, it was impossible to quantify each factor isolated. Translucency and color are highly correlated properties of a ceramic restoration.7,35,36

After the glaze stage, all core materials tested had substantially lower ΔE* values over all substrates, below the clinical acceptability threshold. Two of the zirconia cores (NPZRW and NPZRC) registered ΔE*<1.6, below the clinical perceptibility threshold (except for NPZRC over polished Ag-Au-Pt, which registered ΔE*=1.7). NPALU also performed accordingly in four of the eight substrates. Among all zirconia, NPZRW was the only one to register ΔE*<1. These values originated statistically significant differences between NPZRW and ZZRPW over six of the eight substrates, except polished Ag-Au-Pt and zirconia.

Over those two substrates, NPALU registered ΔE*<1.1 and significant differences to ZZRPW.

The results showed that NPZRW changed its performance from being the zirconia material with the worst %T and ΔE* results at the core stage to becoming the best material after the glaze stage. ZZRPW demonstrated the opposite behavior, as it performed best at the core stage and worst at the glaze stage. Although the literature indicates a stable optical behavior of zirconia cores after the sintering stage,37 some authors recently suggested that this altered behavior of zirconia cores could also result from structural differences induced by the composition, processing method, and initial sintering protocol that accounts for alterations at the sintering of layering ceramic stages.19,27,38

The core material color does not seem to be a determinant factor for the ΔE* values obtained. Initially, all colored cores performed better than white ones, but at the glaze stage, there was no tendency to maintain or contradict that behavior. Among zirconia, NPZRW and NPZRC registered ΔE*>0.5 and <1.7, ZZRTW and ZZRPC registered ΔE*>2 and <2.5, and ZZRPW and ZZRTC registered ΔE*>3 and <3.7. NPALU performed closer to the two best zirconia core materials. This behavior should be considered in core material selection when a decision has to be made between materials from the same manufacturer or between manufacturers. The thickness of the restoration should also be considered since materials that performed closer to the clinically acceptable threshold of 1.6 mm might easily exceed it if thickness decreases.

Regarding substrates, initially, all core materials registered significant differences, but after the glaze stage, the Zirkonzahn materials presented no statistically significant diferences (ΔE*<0.5 between the substrates). Similar results were observed in a in vivo test with posterior restorations made with 0.4-mm zirconia cores (Zeno, Wieland Dental and Technik GmbH & Co, Germany) and layered to 1.5-mm with ZirLiner and IPS e.max Ceram (Ivoclar Vivadent AG, Liechtenstein) cemented with neutral cement over metallic or composite post cores.19 Authors reported no differences between the two substrates, even though it may affect the restoration color. However, in the present study, Nobel Biocare core materials still presented significant differences at the glaze stage (ΔE*>0.5 and <1 between the substrates). Thus, the null hypothesis H03 was rejected.

Over polished Ag-Au-Pt or zirconia substrates, NPALU specimens presented considerably lower ΔE* values than the zirconia materials. One study39 suggested using gold post cores under high translucent restorations due to their esthetic result, biomechanics, and biocompatible properties. Although it observed spectrophotometric differences, it found no diferences between lithium di-silicate and In-Ceram Alumina crowns cemented over ceramic, metal/ceramic, and gold polished/sandblasted cores on clinical conditions.39

Two different processes produced the high-strength ceramic cores tested. NPALU, NPZRW, and NPZRC were all produced by dry-pressed technology and showed the best ΔE* results. Light scattering on polycrystalline ceramic materials results from two different phenomena: irregular phase distribution, spaces or voids at grain boundaries, or grain optical anisotropy.7,17Structural analyses should further investigate processing techniques’ potential role in these characteristics.40

The present study has some limitations. Tooth-shaped specimens could replicate clinical restorations better than the disk-shaped specimens used. Also, increasing the sample size might produce more consistent results. Despite the great diversity of zirconia materials available on the market, this study only included a limited number of zirconia materials due to the need to control for study variables. So, this study can be replicated using other zirconia materials with diferente compositions, sintering temperatures, or color processing techniques to better understand their relevance to restoration color. The present study could not use a spectrophotometer with an integrated sphere, which would help measure the dispersion in the zirconia materials tested and provide better information for interpreting the results. However, using a transmittance spectrophotometer helped obtain information about the degree of translucency of zirconia, which is important to understand the color behavior and influence of the substrate.

Conclusions

Ceramic application decreases the translucency of all core materials, making all colored zirconia cores behave uniformly. Core materials influenced ΔE*, with alumina showing lower values than all zirconia over polished Ag-Au-Pt and zirconia substrates. All high crystalline ceramic systems tested, after 1.2 mm ceramic application, performed under the clinically acceptable threshold over all substrates. Substrates influenced ΔE*, being more critical at the core stage than at the glaze stage.