Introduction

In an increasingly competitive and rigorous business world, the automotive industry being one of the most advanced and competitive in the world, the reduction of costs associated with production becomes one of the main objectives in business day-to-day. The company where this study was carried out production of rubber and plastic components for the automotive industry, operating in central Portugal. Following this line of thought, the department where this study was carried out was the maintenance department.

This project has as main objective the reorganization of the maintenance layout, as well as the improvement / creation of flows and the improvement of the management of spare parts in stock (spare parts). In order to achieve these objectives, the lean methodology was applied, as well as the tools associated with it.

1. Theoretical framework

Six sigma is a rigorous, focused and highly effective implementation of proven quality principles and techniques. Incorporating elements of the work of many quality pioneers, six sigma is aimed at commercial performance with virtually no errors. Sigma, s, is a letter of the Greek alphabet used by statisticians to measure variability in any process. Second(Montez, 2011)six sigma is the definition of results as close to perfection as possible. With the standard deviations determined, 3.4 defects per million opportunities are reached, or 99, 9997%. It means, for example, that an airline would lose 3 bags per million carried.

Because of this, six sigma projects are aimed at creating or modifying processes, contrary to the traditional project approach, where the emphasis is on the product aspect. Usually, the development of this type of project can be divided into five phases, according to the DMAIC cycle.(Brain Engenharia, 2017)

DMAIC (Define, Measure, Analyze, Improvement, Control) is a quality strategy, which belongs to the base of the six sigma methodology, which is based on the data collected to improve processes. The DMAIC methodology selects a problem that has been identified by the organization and uses a set of tools and techniques in a logical manner, in order to achieve sustainable solutions.(Shankar, 2009)

The principles of the DMAIC methodology provide concise definitions for processing customers, their requirements and their expectations. Based on this definition, a plan is developed to collect all process data and measure performance, opportunities and defects.(Al-Aomar et al., 2015)

Second(Aruleswaran, 2010), DMAIC highlights the implantation and implementation of continuous improvement activities in the operational routine, guarantees the flawless execution and produces quick results.

This methodology does not necessarily have to be used in the six sigma methodology, it can also be used as an independent tool. This methodology is divided into 5 stages, defining, measuring, analyzing, improving and controlling.

Define: The define phase begins with the identification of the problem that requires a solution and ends with a clear understanding of the dimension of the problem and with evidence of support from the management, which authorizes the project's progress.(Shankar, 2009)

Measure: In this step, all data and information about the current maintenance situation in the company are collected. The objective of this phase, during the six sigma process, is to obtain as much information as possible about the current process, in order to fully understand it, how it works and how well it can work. Various quantitative and qualitative tools / techniques are available for measurement.(Bikram Singh, 2015)

Analyze: The purpose of this phase is to use the data collected in the previous phase to identify, organize and validate potential root causes. The result of this phase is a list of causes that were responsible for the defects that occurred in the process. The analysis phase involves pure detective work, using clues from the data obtained to establish a hypothesis, which is then tested using simple or advanced statistical tools (Strong, 2003).

Improve: In this phase, ideas and solutions are proposed to eliminate the root causes found. This is a crucial phase, in which, when identifying the root causes, the solutions will be generated and tested by the study coordinator. During this phase, the team's creativity generally helps to generate solutions and achieve a result that emerges in big gains (Aruleswaran, 2010).

Control: In this step, the improvements identified during the previous phase are collected and documented. All information is collected, consolidated and prioritized to assist a final or complete implementation. Implementation plans, as well as change management procedures, will be developed to ensure a successful transition from the solution to the team that will be responsible for supporting the new process (Aruleswaran, 2010).

2. Case study

2.1 Phase 1 - Define

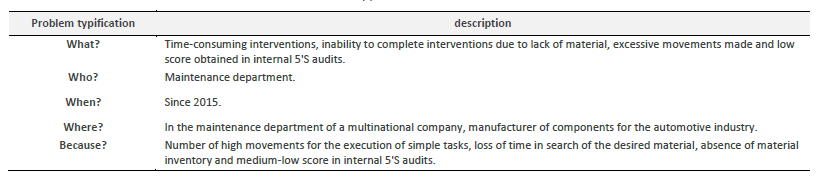

As the name implies, the define step is characterized by the definition of the problem encountered, as well as the context in which the problem is found. The context of the project's application and its objectives are also defined.

Project definition: The study was developed in a multinational company, manufacturer of components for the automotive industry, operating in the district of Viseu, with its main focus being the reorganization and optimization of the layout of the maintenance department. The company employs more than 500 employees and has a turnover of around 38 million euros. It is installed in an area of 18000 m2, with 9100 m2 of covered area. This plant produces components for the engine cooling system, air and vacuum system and for the oil system. It is a company certified by the international standards IATF 16949 (quality), ISO 14001 (environment) and OHSAS 18001 (hygiene and safety).

The voice of the customer: Although this department does not have direct contact with the end customer of the plant, it is considered a department that provides internal services. The customers of this department are the design department, the processes department and the production department, among others, the latter being our largest and most important customer.

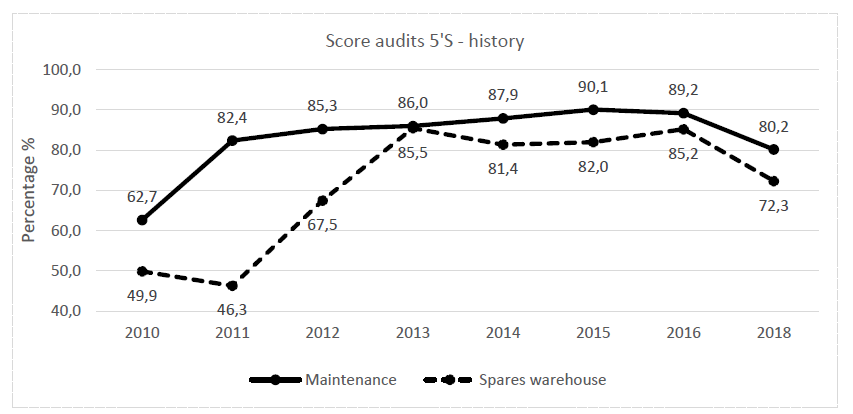

Problem definition: The service provided to the customer was usually carried out in a long time and it was often not possible to complete the intervention due to the lack of material. In a context where every second without producing counts and the interventions performed, or lack of them, directly interfere with the satisfaction and fulfilment of the client's objectives, it is essential to implement actions to improve internal processes and methodologies. In addition to this problem, there is a notable disorganization of the space for the maintenance department and the space reserved for the storage of the material that is consumed, implying that the stock management is done daily and visually, increasing the risk of failure. The industrial unit has implemented the TPM (Total Productive Maintenance) tool. One of the fundamental pillars for the correct and effective application of this tool is the 5'S tool. This tool is audited monthly, through internal audits. Historically, the score obtained by the maintenance department in recent years, on average, was 77%, which is often referred to as a negative point in external audits. Here to characterize the problem, the “5W1H” tool was used. With the application of this tool it was possible to elaborate table 1, with all the essential information for the study and planning of the project to start.

Project objective: To improve the organization of the department, its efficiency and the results obtained in internal and external audits.

2.2 Phase 2 - Measure

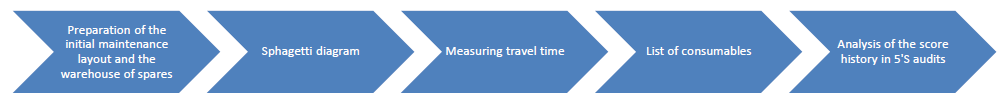

After characterizing the project and defining the objectives to be achieved, the second phase of the DMAIC methodology is then started. In this stage, all data and information about the current maintenance situation in the company are collected. The process was divided into 5 stages, figure 1 .

1st stage - Spare warehouse and maintenance layout.

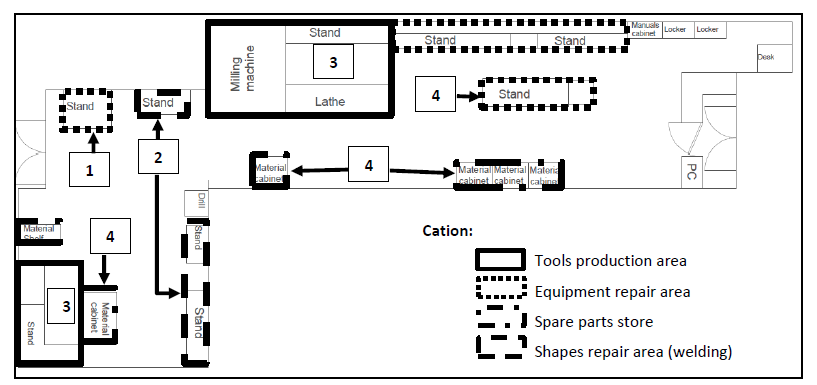

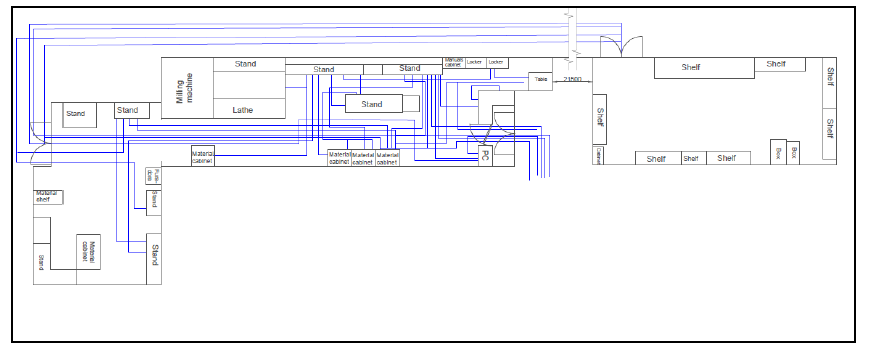

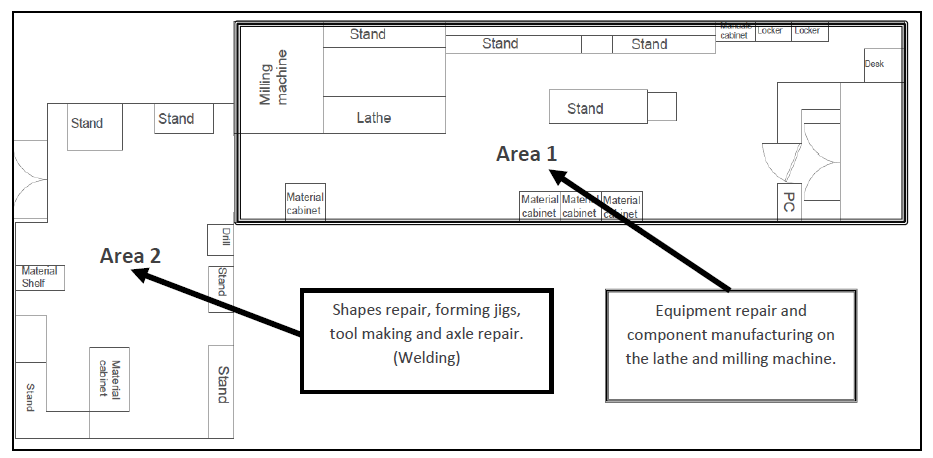

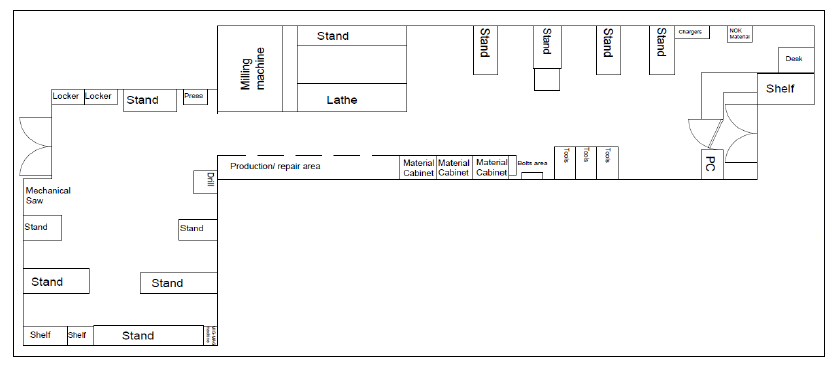

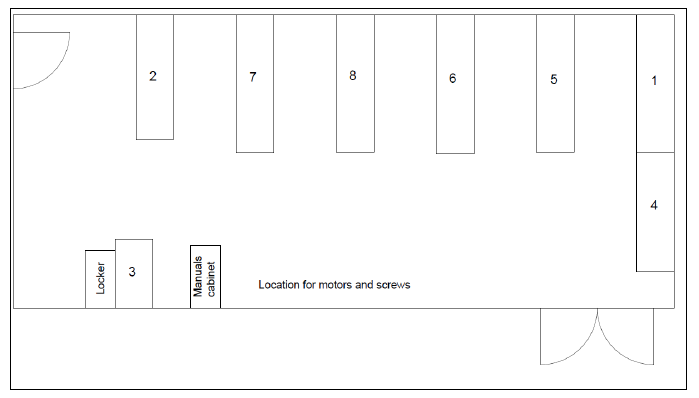

Maintenance consisted of 4 distinct areas, such as tool manufacturing area, equipment repair area, consumables storage area and shape repair (welding) area, figure 2.

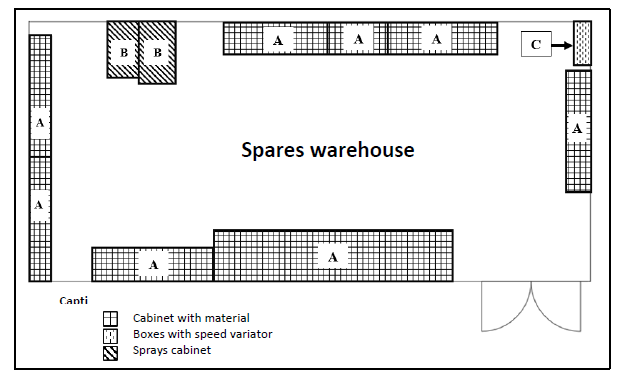

In addition to the space reserved for the repair and manufacture of equipment, maintenance has a second space in its possession, this place is reserved for storing and packing all the replacement material, spare parts (figure 3). As this space has a direct influence on the efficiency of the repairs carried out, and on the time used to carry out the repairs, this space was also included in this study. The total area of this intervention is about 165 m2.

2nd stage - Sphagetti diagram

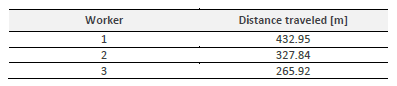

In this step, all movements made by an employee on a normal working day, figure 4, were accounted for and represented graphically, figure 4, noting that the data collection was carried out in the areas that are included in this study, all movements carried out within the manufacturing area were not considered. The data collection was made from three employees chosen at random, during an 8-hour shift, on different days and work shifts, the results obtained are shown in table 2.

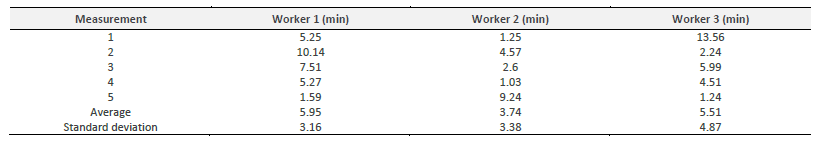

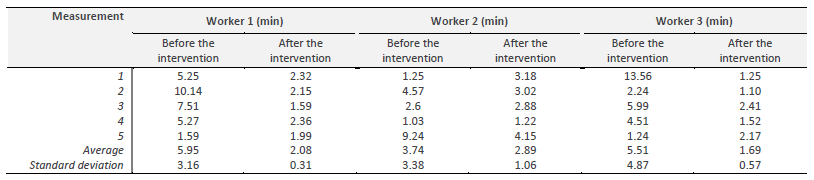

3rd stage - Measurement of travel time to the outside warehouse

In most of the interventions carried out, it was necessary to make at least one trip to the outside warehouse (warehouse of spares). The reduction in time and the number of trips can represent a significant gain, thus increasing maintenance efficiency. The data present in table 3 were obtained by measuring the time that the same three employees took to make the maintenance route - spares warehouse - maintenance, also including the time they needed to find the necessary material.

4th stage - Survey of the most used consumables for equipment repair

In order to organize the material, there was a need to create a list of the material that consumes the most.

5th stage - Analysis of the history of 5'S audit results

The company adopted the use of 5'S audits in order to control, promote continuous improvement and the cleanliness of all spaces. The audits consisted of filling out a pre-defined form by the company with a score being assigned to each item, the score obtained is the sum of the scores for each item. In Graph 1, it can be seen that the score obtained for both maintenance and the spares warehouse has never shown a constant improvement trend, with a setback in the improvements applied over the years.

2.3 Phase 3 - Analyze

After collecting all the data, the third phase of the DMAIC methodology was implemented. The purpose of this phase is to use the data collected in the previous phase to identify, organize and validate potential root causes. The data analysis was divided into three stages, represented in figure 5.

1st stage - Brainstorming

It is a technique used to help a group of people to create as many ideas in the shortest time as possible and aims to help participants overcome their limitations in terms of innovation and creativity. (Santos, Sd)

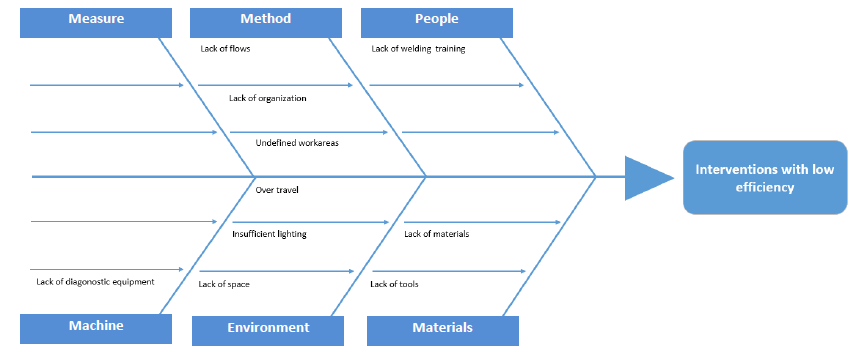

All employees belonging to the maintenance department were asked to give their opinions on the difficulties they had to face on a daily basis. The difficulties encountered were grouped and synthesized using the Ishikawa diagram.

2nd stage - Ishikawa diagram (cause-effect diagram)

The main difficulties were distributed among the different categories present in the diagram, figure 6, making it possible in the end to obtain the possible cause / origin of the initial problem. The cause found was interventions that are performed inefficiently and ineffective.

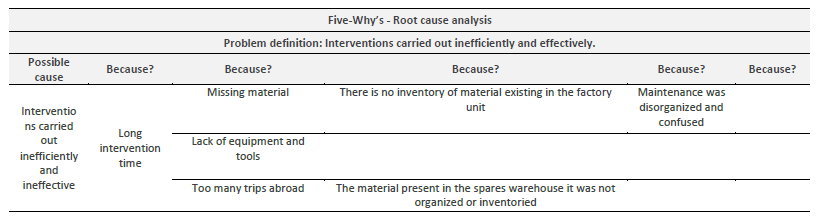

3rd stage - Five-why’s

In order to find the root cause (s) of the problem, the five-whys tool was used. Once the possible cause of the problem has been identified, it is necessary to further determine the root cause, so that it is completely eliminated. Second (Rafinejad, 2007), the "Five-whys" method is an effective technique that can be used to ensure that symptoms and effects are not confused with the root causes of a problem. The "Five-Whys" begin to ask the question "why" to the problem that has occurred; the question is asked "why" again; repeating the "why" question five times, or until answering the "why" question becomes difficult. In this case, the root cause has probably been identified.

After applying this tool, it was possible to determine the root causes of the problem that was initially posed, table 4. The causes found were: maintenance was disorganized and confused, as can be seen in figure 7, equipment and tools and material were missing present in the spa warehouse was not properly organized or inventoried, figure 8.

2.4 Phase 4 - Improve

Once we found the root causes for our problem, we entered the fourth phase, the improvement phase. In this phase, ideas and solutions are proposed to eliminate the root causes found.

Maintenance: The first phase was to ask each of the maintenance employees to graphically represent their opinion and vision regarding the new layout. Then, all the drawings presented were analyzed and a list was created with the common points found.

Common points found:

Division into two distinct areas, equipment repair area and tool manufacturing area (welding);

Definition of different areas for the repair of the various equipment existing in the factory;

Creation of benches with all the necessary material for the repair available.

Taking into account the common points found in the projects elaborated by the collaborators, the list of material needed for each work area and the three objectives initially proposed, the design of the new maintenance layout began.

1st Step - Division and separation of maintenance in two areas

Area 1, figure 9, was used for all types of equipment repairs, storage of material in stock, repair of wooden jig's and also for the manufacture of components in the lathe and milling machine, it is important to note that in this area there is no there is the welding process. Area 2 was reserved for the process of repairing shapes, forming jigs, making tools and repairing axes. In this place the use of the welding process is allowed.

2nd Step - Definition of the number of benches required

In area 1, the following workbenches were defined, workbench for bonding and electronic towers, workbench for connector / clamp machines, workbench for various repairs (pumps, motors, weaving heads), workbench for wooden jig's and workbench support workbench. In area 2, the following benches were defined, such as, two benches for repairing shapes (shapes), two benches for the manufacture of tools and a bench for repairing the axes.

3rd Step - Elaboration of the final layout

Considering all the points and suggestions previously discussed, the new maintenance layout was designed. The proposed layout, after being analyzed, was not approved, as it had negative points in its configuration.

1st Point - Plenty of free space, conducive to the accumulation of material.

2nd Point - Although there is a division between benches, the spacing between them allowed the use of the two benches simultaneously.

3rd Point - Impossibility to work on both sides of the bench, this point is important, as the central bench has been removed, and there are certain repairs that require two people.

4th Point - Place for placing the specific material for each work area, it could hinder the repair of equipment.

5th Point - In the welding area (area 2) there is the possibility of sparks and material being removed into the corridor, which may affect the people who pass there.

With all the negatives mentioned above and gathering more opinions from maintenance employees, the layout was corrected and resized.

When analyzing the new layout, figure 10, we can highlight, in area 1, the layout of the workbenches, all of which allow you to work on both sides. The specific material was placed on the wall, next to each bench, occupying the smallest possible space. A specific location was also added to charge the equipment batteries. A storage area has also been created for all screws. A reserved area was added to all non-compliant material or material for return to the supplier. In area 2, the layout of the workbenches followed the layout adopted in area 1, the workbenches were protected at the front, avoiding the projection of sparks and material that is being removed. A hydraulic press was added, which is important in the axle repair process.

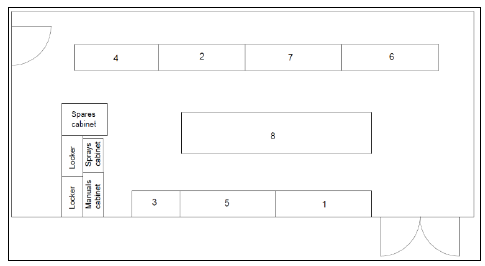

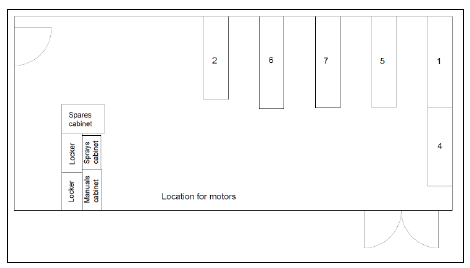

Spare warehouse: This space is reserved exclusively for the packaging of all replacement parts for all equipment present in the factory. In preparing the layout, the team defined 3 points to take into account when defining the new layout.

Points to consider:

- Division of spares warehouse depending on the areas present in the production process;

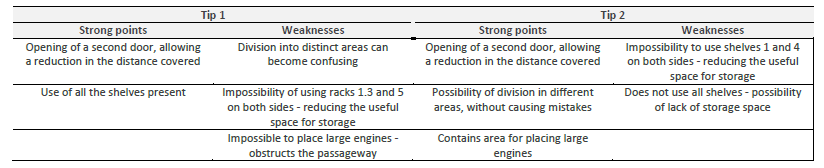

Taking into account the points mentioned above, a brainstorming and approval by the managers were selected two suggestions for the new layout. Then the two suggestions were analyzed, figures 11 and 12. All employees of the maintenance department met with the objective of finding the positive and negative points of the two suggestions. The results obtained are shown in table 5.

The suggestion that contains the least number of weaknesses is number 2, but as it still has some weaknesses, it was decided to make improvements to the layout presented. With the final layout, figure 13, it was possible to eliminate the weaknesses previously presented. The shelves were distributed as follows:

Bookcase 1 - Vulcanization material

Bookcase 2 - Electrical material

Shelf 3 - Consumables (sprays, sandpaper, adhesive tape rolls, brushes)

Rack 4 - Hydraulic seals and tubes

Shelf 5 - Extrusion material

Bookcase 6 - Finishing material

Bookcase 7 - Pneumatic and electrical material

Bookcase 8 - Different material

A space was also created for maintenance employees to place their personal objects. The area for placing large motors was also used to place a rack with all the variety of screws that are used, thus creating a safety stock.

2.5 Phase 5 - Control

Upon completion of all proposed changes to the maintenance layout and spar store layout it is necessary to control and maintain discipline in order to keep the spaces always tidy and as optimized as possible.

2.5.1 Presentation of results

In order to assess the effectiveness of the interventions carried out, the measurement process was used again. The sphagetti diagram was again elaborated and the time spent on travel spares warehouse, it should be noted that the data collection process, as well as the assumptions taken into account in the measure stage, were maintained in this new measurement. Finally, the results obtained in the 5'S audits after the interventions were analyzed.

Sphagetti diagram

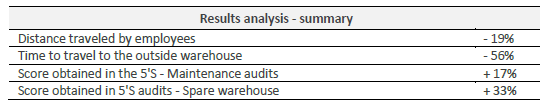

Using the same method as the measure step, the distance of the same three employees was again represented graphically and the distance calculated after the interventions in the maintenance department were completed. Collaborator 1 covered 275.91 meters, Collaborator 2 covered 312.31 meters and the third 240.74 meters. Comparing the values obtained before the intervention with the values obtained after the intervention, the distance had a decrease of 19%.

Measurement of travel time to the outside warehouse: after all the planned interventions were carried out, the time required to carry out the maintenance shift - spares warehouse - maintenance was again collected. The collected data are shown in table 6, comparing the average of the times obtained before the intervention with the times obtained after the intervention, there was a decrease of about 56%. The results of the calculation of the standard deviation show lower values than those obtained before the intervention, being also little dispersed values, the highest value obtained was 1.06, contrasting with the 4.87 obtained in the first measurement.

5'S audits

The modification of the layout and its organization, both in terms of maintenance and spares warehouse, already has results reflected in the internal 5'S audits. Audits are carried out until the 15th of the respective month. The first phase of the intervention ended at the end of April, with the results being passed on in May. The score obtained in the month of May was 70%, which is the same as that obtained in the audit in the previous month, this stagnation is justified by the need to occupy area 2 with material and tools from area 1, impairing tidiness and the definition of the layout that area.

The second stage of the maintenance intervention ended at the end of May. The results of this intervention are reflected in the audit for the month of June, obtaining a score of 82%. The results show a significant improvement, having a 17% growth compared to the results obtained in the month of May.

Spare warehouse

Respecting the schedule developed in the first phase of the DMAIC methodology, the intervention / reorganization of the spares warehouse it started in the first week of July and ended in the third week of August. The score obtained from the beginning of the year until the month of June showed a downward trend (77% in January and 60% in June). The decrease in the score observed in the months of April, May and June is justified by the placement of material and machinery resulting from the intervention carried out in the maintenance area. In July, the score reversed the downward trend shown in previous months, having increased by around 33%, reaching 80%. It should be noted that, as in the month of August no 5'S audits are carried out, the audit related to the month of July was postponed until the completion of the spares warehouse intervention.

The results obtained with the implementation of the measures previously determined are shown in table 7.

2.5.2 Defining the control plan

The control plan consists of the 5'S audits carried out internally, to ensure that everything is being carried out and according to the project that was presented, correcting if necessary, the non-conformities pointed out by the auditor. It also serves to control audits carried out by external auditors, following up on any non-conformities or opportunities for improvement found. The main objective is to always be implementing improvements, year after year, allowing for an increase in efficiency in the interventions carried out and also a good management of the space and the necessary material.

2.5.3 Limitations

The period available for application of the project, associated with the fact that the factory is working continuously and that there is no team dedicated to planning and subsequent application of changes in the factory, did not allow the results obtained to have a greater expression.

Conclusion

Despite these limitations, the three objectives initially proposed were met. Compliance with the first objective, reorganization / restructuring of the layout, allowed the distance traveled by employees to decrease 19%, as well as the time required to travel to the outside warehouse, a 56% reduction, increasing the degree of efficiency and quality, complying with all safety standards. The score obtained in the 5'S audits showed improvements in the two interventions, maintenance and spar storage, increasing by 17% and 33%, respectively. After analyzing the results obtained, it is concluded that the working group reached the root cause of the problem and the solutions defined had a positive impact in eliminating the root cause and the problem initially proposed.

Acknowledgement

I also express my thanks to the company where this dissertation was held, in particular to the general director, to the director of the maintenance department and to all my maintenance colleagues, for the help given, for the ideas shared and for the support provided.

I thank my advisor, Professor Doctor Paulo Joaquim Antunes Vaz and Doctor Rosa Silva, responsible for the library, for their support, guidance, full availability, all the encouragement and teachings transmitted throughout this long stage.