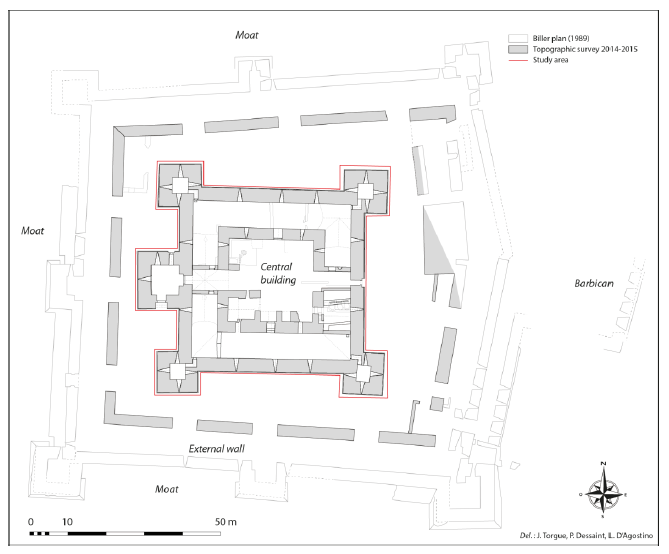

The archeological study of the central building of the castle of Belvoir (Fig. 1), erected by the Hospitallers of Saint John around 1168, has revealed that a great number of iron staples were used in the construction of its exterior facings. Beside the fact that this unusual process required an exceptionally high supply of metal for this specific work, the reasons for such an implementation raise questions.

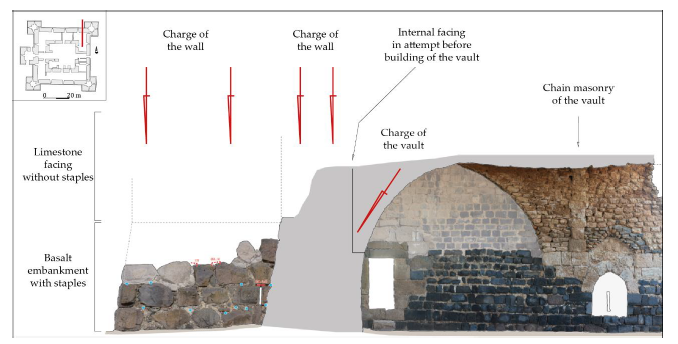

Thus, a more in-depth study on the staples was launched in 2013, first on a punctual basis, then more systematically. Several of these staples were at the level of the arrow-slits, where they joined two blocks of the jambs, below the lintel. The identification of the location of the staples was a collaboration of Olivier Guyotat1 and Robert Kool2. Robert Kool made it possible to have a metal detector on the site and carry out a test to try and locate non-visible staples on the facings (Fig. 2). Most of these staples are in fact only perceptible on the levels of the walls, on the top face of the blocks, in the form of sealing holes; they are visible on the facings only when the plaster, having greatly deteriorated, reveals what is under the skin of the masonry.

Fig. 2 West door of the inner building; basalt embankment and upper siding in limestone. (© L. D'Agostino).

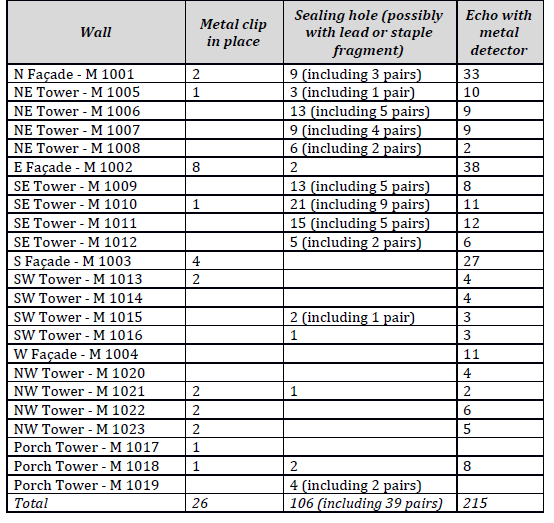

During the 2014 and 2015 missions, a detailed survey of the elevations of the interior reduct based on the crossed methods of topography and photogrammetry was done to provide a support of study and metric analysis for the whole building. This survey covered the entire exterior and interior elevations of the main building3. On the survey report provided by the photogrammetry, we systematically located the staples on two sides of the reduct: the eastern façade and the southern façade, as well as on the facings of the towers on the north-east and south corners4. A systematic visual analysis allowed us to identify the entire staples, which are few in number, and their sealing holes, which may still include either the lead sealant, or some metallic residue from the staple itself. Then, we used the metal detector to conduct reactivity tests on the staples still in place, which allowed us to adjust the sensitivity of the machine. In the end, to cover all the masonry, we did systematic scanning of the facings. In 2015, this research was extended to the entire central building of the castle (Fig. 3) and tests were carried out on the outer wall.

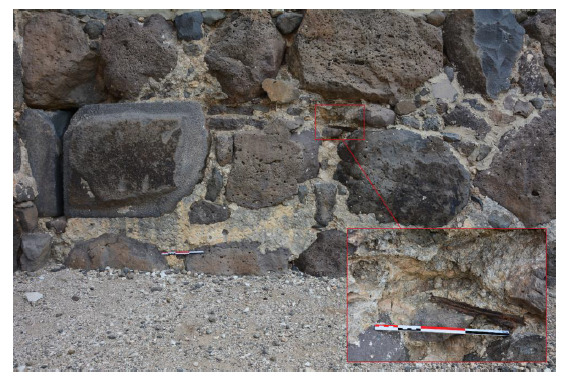

Fig. 3 Construction of cyclopean blocks, with joints of plaster with scale-shaped incisions. (© L. D'Agostino).

The place of metal staples in construction

Construction methods of the building

The central building of Belvoir castle is built on a regular square plan of 48.8 m east-to-west by 48.35 m north-to-south. It is flanked in the corners by square towers of about 11 m on each side5. A rectangular porch-tower built in the center of the west façade defends the main access to the reduct. It is more imposing than the others, with a north/south length of 15.24 m and an east/west width of 11.14 m. While the interior elevations of the reduct are in a fairly good state of preservation, sometimes all the way to the vaults covering the ground floor, this is not the case for the exterior walls. The external facings are currently observable on very variable heights, from approximately 1.65 m at the level of the northeast tower to 6.80 m at the level of the west wall of the central building. This poor state of preservation obviously hampers our understanding of the architecture of the building, which is only partial: only the ground floor, which has been preserved, is understandable, while the upper floor remains very difficult to read, in a very localized way at the level of the central courtyard. Major restoration work was carried out after the excavation of the castle at the end of the 1960s. Although this work was limited to the internal facings of the reduct, the external facings of the walls have been extensively restored, sometimes affecting 50 and 80% of the surface of the facings. Before considering any analysis of the construction, it was therefore necessary to proceed to a critique of the authenticity of the monument.

The external elevations of the Belvoir interior reduct show a very homogeneous construction method (Fig. 4). Whether at the level of the towers or the central building, the lower parts of the walls are systematically shaped as embankments built with large blocks of rough or split basalt whose dimensions range from 73 by 31 cm to 90 by 145 cm or 102 by 124 cm (Fig. 5). While the courses are adjusted, the variable shapes of the blocks require the use of many smaller elements, of shards of basalt or sometimes limestone, to shim the cyclopean blocks; the joints are then completely covered with a plaster with scale-shaped incisions (Fig. 6).

The courses reach an average of 0.84 to 0.89 m in height. The slopes of the embankments average around 80°. Their height is no longer observable everywhere, but the west wall presents an observable embankment with a height of 5.20 m and a slope of 82°; the wall is 3.59 m thick at its foot, and 2.78 m thick at the top of the embankment. At the north wall of the gate tower, the embankment is 3.13 m high, with a slope of 80°; it is 3.87 m thick at the foot of the facing, and 3.13 m thick at the top of the embankment.

Only the corners of the towers and of the “endless hall,” as well as the frames of the arrow slits and of the doors were treated more carefully, with large squared basalt blocks with edges carved with a miner’s iron. The center of the side with facing has been rustically worked with a pickax or a stub hammer (Fig. 7) and the pattern of the boss catches the light. Beside this aesthetic aspect, and the defensive role of the boss which can deflect a cannonball, this process makes it possible to have a sharp edge on the corner of the block, which facilitates the assembly of the quoin blocks by allowing the stones to be aligned on top of each other, thus saving work time compared to making a block with a fully smoothed side.

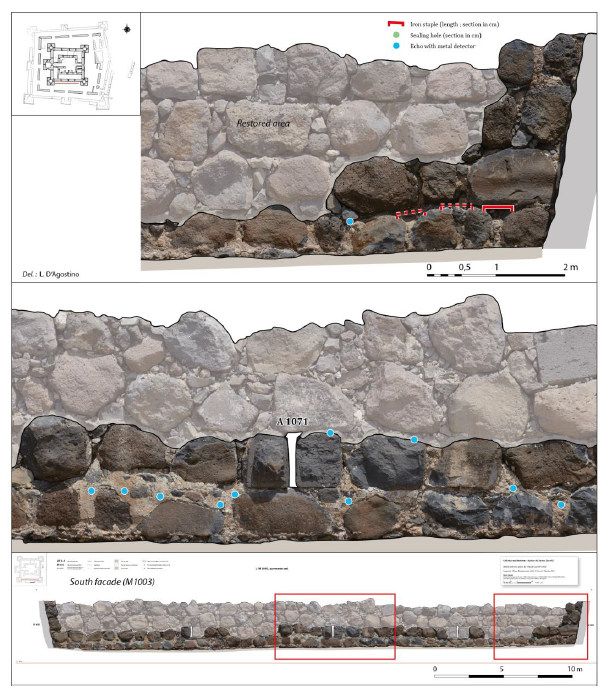

Fig. 6 Localization of the staples and of the echoes with metal detector in the external siding of the southern wall (M 1003) of the central building of Belvoir Castle. (© L. D'Agostino).

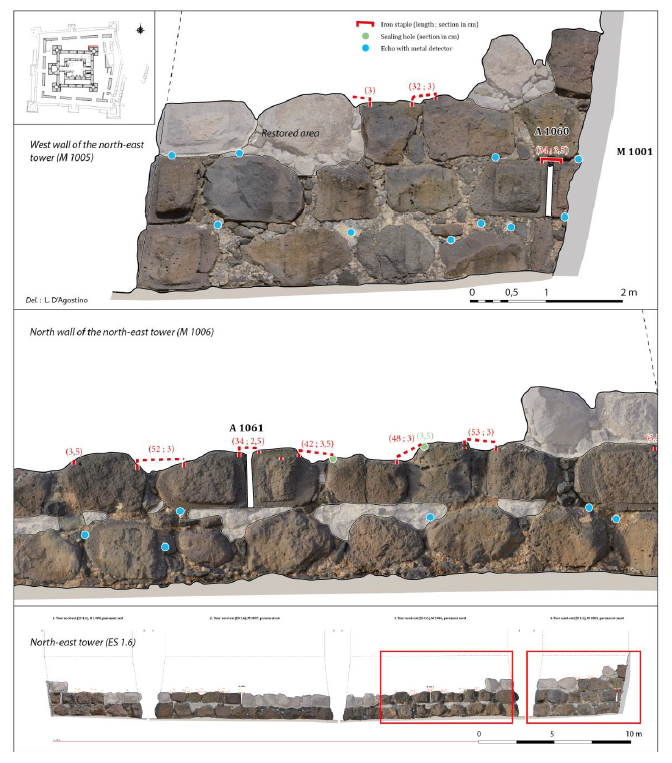

Fig. 7 Localization of the staples and of the echoes with metal detector in the external siding of the eastern wall of the central building (© L. D'Agostino).

The building method changes radically at the top of the sloping bank. To the west, east, and occasionally north, the basalt facing gives way to a facing of large regular brickwork of yellow beige limestone. It is poorly preserved and heavily restored, and therefore difficult to characterize. The carefully squared limestone rubble stones are flattened on their siding faces, while their tail is more coarsely shaped. Their dimensions vary on average from 48 by 61 cm to 84 by 61 cm and some still bear traces of barely protruding tabular boss. Pieces of limestone and basalt are often used to adjust the layers and shim the rubble stones between them.

The binder consists of lime mortar, yellow beige limestone and basalt shards. Large nodules of poorly cooked lime are visible in the mortar. At the level of the basalt embankment facings, the small blocks are covered with a stone coating, leaving only the cyclopean blocks visible. The coating, spotted in several places on the exterior façades, has been pressed on the facing with a trowel, leaving scale-shaped traces. This construction method is perfectly identical to that observed on the internal facings of the central building’s galleries.

Spatial distribution and staple placement method

In the central building, staples are observed only on the external facings of the peripheral walls of the reduct and towers, only at the basalt embankments’ level. No staple has ever been seen at the level of the large limestone brickwork facings. They are easily spotted and almost systematically present at the level of the arrow slits, where they connect the arrow slits’ jambs on the soffit of the lintels. They can be observed very regularly on the towers straddling the corners of the central building, more loosely on the façades. However, they are regularly visible at the clamping points of the towers and the façades. The most favorable areas are the leveling courses of the walls, where the top faces of the blocks are bare; elsewhere, mortar on the joints makes their observation more difficult (Fig. 8).

Fig. 8 Localization of the staples and of the echoes with metal detector in the north-east tower of the central building (© L. D'Agostino).

Moving apart the facings, restored after the castle was cleared, allows for some counting. On the south façade (M 1003), on the first course, which is 37.80 m long and consists of 43 blocks, four staples are attested and 23 echoes were perceived (Fig. 9). On the less well-preserved second course, four other echoes have been detected. On the eastern façade (M 1002), on the first course, 8 staples are attested, as well as 17 echoes, on a length of 36.50 m and 36 large basalt blocks (Fig. 10). The towers give out even more information and show careful stapling. The northeast tower reveals 20 attested staples and 30 echoes, on all the courses of each wall, particularly at the level of the quoining with the façades (Fig. 11). On the first course of the north wall (M 1006), made up of 10 blocks, 8 echoes have been detected; on the second course, made up of 11 blocks, 7 staples are attested. On the eastern wall (M 1007), on the first course, made up of 10 blocks, 9 echoes have been detected; on the second course, made up of 13 blocks with only 5 in place, 5 staples are attested. The south-eastern tower, preserved on only two courses, shows an equally large number of staples with 36 staples attested and 37 echoes.

The survey conducted confirmed the presence of 93 staples, whole or not (26 in place and 67 manifested by their sealing holes) and 215 potential staples around the periphery of the central building, preserved on a small half of the original height of the embankments. While the stapling of the embankments seems particularly substantial to the north, east and south, it appears to be looser to the west, as no staple was observed on the west façade (M 1004), which nonetheless has 11 potential echoes; the southwest tower shows only 4 staples in place as well as 14 echoes. The porch-tower, whose quoining with the west façade testifies to its existence since the origin of the castle, also has a few staples, but in limited number: 6 staples or traces of staples in place and 8 echoes.

Fig. 11 Details of the staples and sealing holes; staple discovered during the excavations of Meir Ben Dov (© O. Guyotat, A. Flammin).

The staples systematically link two contiguous blocks on the single course of a single wall. Some connect two projecting or receding corner blocks, always on the same course, at the junction between two walls. All of the staples observed are sufficiently set back from the face to be hidden by the mortar beds and the joints. Only the staples at the top of the arrow slits were therefore visible across the width of the slit on the soffit of the lintel. The staples are placed horizontally on the top face of the stones. However, some elements raise questions about their use: a reserve can be noticed on the soffit of the right block of arrow slit A1065 on the eastern façade; two other reserves were observed on the boss on the northwest corner block of the second course of the north wall of the northeast tower (M 1006), as well as on the boss of the outer face of the right jamb of arrow slit A1061, on the same wall. Without more, we can’t tell whether these are one-off reinforcements or peniments.

Staples: morphology and quantification

Morphology of the staples

In the elevations of the central building, the length of the staples measured and the distance between the sealing holes of two neighboring blocks vary between 19 cm and 92 cm, with most sections at 3 by 3 cm, and some variations at 4 by 2 cm, 3 by 2 cm and 2.5 by 2.5 cm. In general, the sealing holes are round, with a depth varying from 2.5 to 7 cm. The staples were shaped the same: an inverted U, with 5-to-6-cm-long bends and sealing clamps at the end of both bends.

An analysis of the staples left in situ on the castle’s sloping banks was done, as well as a study of the staples taken during Meir Ben Dov excavations, which are kept in the archaeological reserves of Beit Shemesh, west of Jerusalem. A small batch of staples from demolition material could be measured and weighed to assess the quantity of metal needed for the site and the methods of installation.

At both ends of the iron staples are clamps used for lead-sealing in the reserves carved in the stone. The metal parts are not standardized to adapt to the blocks’ various modules. They measure on average between 0.30 m and 0.50 m in length, and weigh from 2.1 to 2.4 kg. This variation in size and weight means that the staples were not brought in as finished products, but that their made-on site, as needed. It is likely that the blocks had to be laid and the sealing holes pierced before the staples could be manufactured and forged to the right dimensions. This procedure obviously requires the presence of a continuously operating forge on the construction site, in its immediate vicinity. The iron was probably transported and delivered to the site in the form of relatively standardized bars, with dimensions varying on average from 2.5 cm by 2.5 cm to 2.5 cm by 4 cm. The blacksmith could then cut them at will by heating them at the place of the cut, which made it possible, at the same time, to shape the bend and the clamps at the ends of the staple. The location and mode of operation of the forge are currently unknown (specialization in staples or, at the same time, maintenance of tools used for basalt quarries in the ditches and stone cutting?).

The question of the origin of the iron remains. Did it come from areas in Jordan beyond the Dead Sea, which would have required relatively perilous transport in those troubled times, or did it come from old ancient sites? This solution would seem the most likely, given that the ancient occupation of the site is believed to date from the period of the Second Temple and would have lasted until the Byzantine period, marked by the remains of a synagogue. Furthermore, ancient cities have been identified in the region for a long time, such as Beit She'an, located south of Belvoir. The reuse of ancient stones, marble or limestone, in the walls of the castle, attesting to this use of material recovery, corroborates this hypothesis.

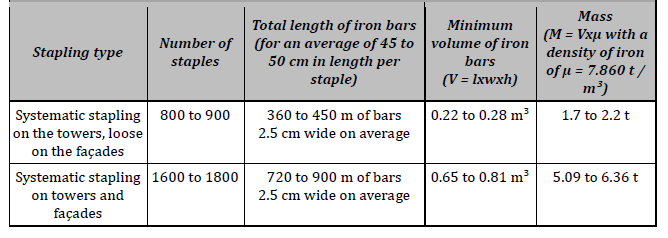

Attempt at quantification

Based on the survey carried out on the exterior facings of the sloping banks and the analysis of the staples of Beit Shemesh, we attempted to quantify the number of staples attested or perceived as an echo with the metal detector, and to assess the quantity of metal needed for the construction site. Based on the count of 308 staples or echoes with the metal detector at the level of the joints and on the conservation of the embankments equal to half their original height, it is possible to consider that the construction of the sloping banks required at least 800 to 900 staples, considering a systematic stapling on the towers, between each block and on each course of the slanting bases, and a looser one for the façades, with particular emphasis being placed on the quoins with the towers and the first two courses. A more systematic stapling, on each course and each block of the embankments of the towers and façades, would require 1,600 to 1,800 staples, but it is far from being demonstrable.

If we consider that the average length of the staples varies between 45 and 50 cm, with many variations between 25 and 92 cm, for an average side of 2.5 cm, we can evaluate the following values for the quantity of iron needed for the construction of the central building.

Even a nonsystematic stapling represents a significant length of iron packaged in the form of bars, between 360 and 450 m in length, but in the end, it only represents a fairly small volume, between 0.22 and 0.28 m³, i.e. 1.7 to 2.2 t of iron. A more systematic stapling of the embankments of the central building brings our estimates between 5.09 t and 6.36 t, which is much more significant, both in terms of transport and on-site logistics, and in terms of financial impact on construction. But without a verification by sounding in the masonry of the real presence of a staple at the level of the echoes delivered by the detector, it is difficult for us to narrow down the ranges of this quantitative estimate, which remains very broad.

In conclusion, the questions concerning the site concern first of all the distribution of these staples and their role in the construction: the staples are not only present at the level of the archery windows, where they consolidate the arrow slits, but also more regularly with each facing course of the embankments and at the level of the quoining blocks connecting the towers to the central building. These indications tend to demonstrate a constructive and structural role for the staples. Not only can they be used to consolidate masonry while the mortar dries, which can take several months for walls over 3 m thick, but they can also be used as horizontal ties in the facings, preventing one of the blocks to slide in the event of a catapult ball impact for example. The presence of embankments and the use of rough blocks which are often rounded perhaps justify the use of these staples all the more. The embankments cause a transfer of the vertical loads of the elevations from one base to the other behind the facing, and not to the base of the facing itself. The load of the elevation can thus cause a displacement of the blocks towards the outside which are “pushed away” by the blocks located higher. The staples thus act as shackles, connecting if not all of the blocks, at least the majority of the blocks of the embankments of the exterior facing between them. It should be noted that no staple has been identified inside the central building, neither in the upper part of the walls on the areas built in limestone, nor on the reused limestone rubble stones, which could also have preserved evidence of the presence of these staples. We must therefore deduce that the staples were used only for the embankment parts and for the exterior facings, which were potentially subjected to shelling by war machines.

The use of these staples in the embankment wall of the enclosure also provides information on the progress of the work. The archaeological study of the walls showed that the enclosure of the interior reduct was built first and we have seen that the use of staples in the sloping bank was linked to the need to reinforce the masonry during construction. This practice seems essential, if we consider that the first phase of construction was carried out very quickly. The architectural analysis of the endless hall and its vaulting confirms this hypothesis. Indeed, the construction of the barrel vaults on the endless hall, which develops around the interior courtyard, was carried out from the inner walls of the central building. Planned from the time the sloping bank was built, as attested by the reserve at the top of the walls, the vaults are built at a later stage, under the shelter of the walls. We can therefore wonder about the reasons for a construction emergency. Belvoir was the first castle of the Order of Saint John to be built in Galilee in the second half of the 12th century. It is certainly a defensive castle, but it does not seem to be immediately threatened by the enemy. Its position not only guarantees a Hospitaller presence in the region, it also constitutes a prestigious landmark visible from afar and, from its foundation, marking the territory with the colors of the order: the black of basalt and the white of limestone.