1. Introduction

It was Leonardo da Vinci, one of the most important personalities of the Renaissance, who stood out, through his drawings of analysis and observation from the composition of the physical systems of the human body as a machine. Also, by the construction of schemes of physical operation that synthesize the laws of physics and that, later, originate the mechanical solutions designed by himself. That is, Leonardo da Vinci would have a dual ability: the ability to analyze an engineer's own characteristic and visual thinking, a cognitive strategy proper of a Designer.

The relationship between Design and Engineering has not its genesis in the 20th century. But it was in this century that the advantage of this association was perceived and came into existence. In fact, much of the products that are part of contemporary modernity could never have been produced without the support of applied scientific knowledge. From the beginning of mass production in the early twentieth century came the need for bringing the two disciplines together: Design and Engineering.

Design and Engineering are two separate and independent disciplines, however, much of their applied field overlaps. Although the Design practice shows an obvious vocation for the design of products and systems of innovative objects, Engineering should have a complementary and supporting function to the Design practice. The Engineering of Design, therefore, is a concept that can refer to different stages of the Design process. In the case of the product development process, for example, Engineering may be present in several stages. Or it may also emerge at an embryonic stage, in the concept of Design, or later in a phase of industrialization of the product.

The technical vocation evidenced by Engineering is devoid of Design thinking. That is, too focused on the problem and not on the solution. Design thinking allows a truly innovative global solution, but without Engineering, it can easily fall apart because it does not comply, for example, with economic requirements or because it fails to be technically industrialized.

2. The Process of Engineering Design

According to ABET (1), a definition for Engineering Design is: “the process of devising a system, component, or process to meet desired needs. It is a decision-making process (often iterative), in which the basic sciences, mathematics, and engineering sciences are applied to convert resources optimally to meet a stated objective. Among the fundamental elements of the design process are the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation.” (Ertas & Jones, 1992, p. 2) [1].

According to Ertas & Jones (1992) [1], which uses the definition of ABET, the concept of engineering design intertwined with the process of design, defined above in the sense that encompasses the Design. However, the main difference, according to this author, is the use of the basic sciences, mathematics, and engineering sciences in the decision process of the Design process.

Similarly, Eggert, defines Engineering Design as being, “(…) the set of activities that lead to the manufacture of exciting new products such as aircraft, automobiles, home appliances, and hand tools as well as the construction of new facilities such as refineries, steel mills and food processing plants. It is a pursuit that challenges our analytical abilities and our knowledge of mathematics, the sciences, and manufacturing to find solutions that work better, last longer, and are easy to maintain and repair.” (Eggert, 2005, p. xiii) [2].

This definition reveals the industrial side of Engineering, that is, as a set of activities whose objective is the manufacture of new products and industrial facilities. It should be noted that Eggert (2005) [2], like Ertas & Jones (1992) [1], evokes scientific, mathematical, and applied engineering knowledge. That is, it reproduces a penchant for the industrialization of Design using the knowledge of basic sciences, mathematics, and engineering sciences (or science applied to engineering).

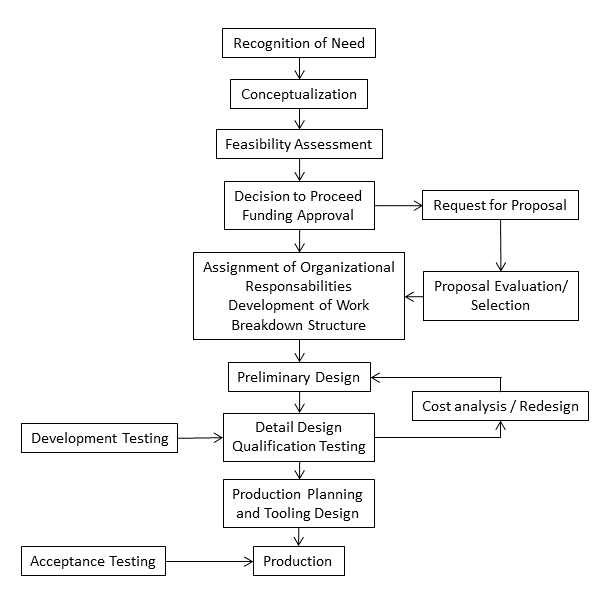

The Ertas & Jones (1992) [1] Design Engineering model, Fig. 1, shows a trend towards product development after the conception. That is, a propensity for feasibility assessment, cost analysis and development test. Stages where the use of Engineering tools based on scientific and mathematical models have a strong decisive character for the detailing and industrialization of the Design.

Also, regarding the Ertas & Jones (1992) [1] model, the stages of recognition of need and conceptualization can and are often shuffled as recognized in his work, “the design process can be initiated based on an idea for a solution to an existing or identified need or from an idea for a product or process for which it is thought a need can be generated. (…) In many projects the «need» is identified by an organization other than the one that eventually accomplish the effort. This is the case for most projects sponsored by government organizations; in these situations, the conceptualization and feasibility assessments will normally be completed before an RFP (2) for the design, development, and production phases is issued.” (Ertas & Jones, 1992, p. 5) [1].

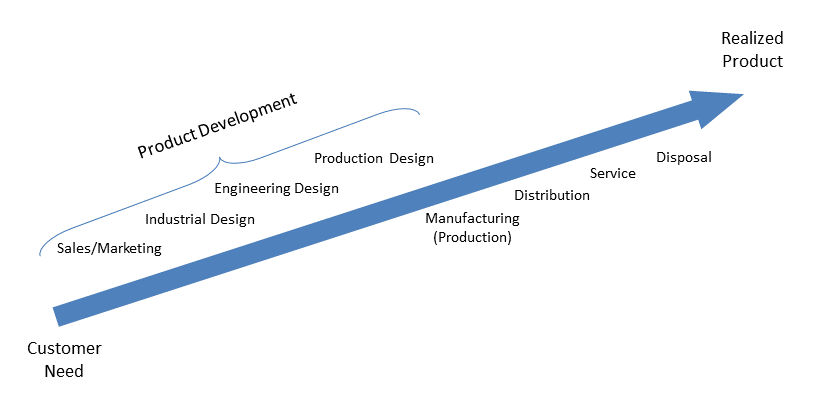

The Eggert (2005) [2] model, Figure 2, is a model of the product realization process. This model represents how the customer's need is transformed into product realization. Eggert (2005) [2] proposes definitions for the different steps of the presented process diagram. Thus, the Industrial Design activity aims to “focus on how the new or revised product idea is compatible with the costumer’s anatomical limitations and/or aesthetic trends in the marketplace. Often the industrial design group will prepare an artistic rendering or a physical model that illustrates basic product form, color, texture, and intended functionality.” (Eggert, 2005, p. 12) [2].

3. The Process of Product Design

The post-war and the need for a new impetus in the industrialization of the world forced the scholars to devote their research to the problematic of the Design process. This issue was mainly focused on the systematization of a Design process that would guarantee a methodology for the development of the industrial product. However, the approach to an institutionalization of a Design process has been filled with controversy. Some scholars have opposed this type of approach, arguing that the practice of Design should be free, in creation and not placed from a strictly logical point of view.

Design can be defined as a process because it is possible to segment it, in a linear flow of different stages. Thus, it is possible to mark the design process in the flow between the characterization of an opportunity or problem until the ideal solution is discovered. Victor Papanek (2011) [3], states, “The planning and patterning of any act toward a desired, foreseeable end is the design process.” (Papanek, 2011, p. 322) [3]. Author, Kathryn Best corroborates the following by speaking of the Design process as a “(...) series of methods that are assembled to better serve the nature of each design project or issue.” (Best, 2009, p.112) [4].

Jones (1992) [5], in his work Design Methods, argues that the goal of studying Design processes and demonstrating them is to clarify the work process developed by designers. The Design methods are nothing more than attempts, to make public the thinking of the designers and externalize the process of Design.

Therefore, Jones (1992) [5] characterizes the Design process by systematizing it, “(...) includes three essential stages: analysis, synthesis and evaluation. These can be described in simple words as 'deconstructing the problem', 'rebuilding the problem in a new way' and 'testing’ to discover the consequences of implementing the new arrangement” (Jones, 1992, p. 63) [5].

The three major steps for systematizing the design process that Jones (1992) [5] presents are nothing more than the steps that designers have become accustomed to in pursuing their profession. The analysis phase is nothing more than the deconstruction of a problem as soon as it is placed. It is in this stage that the study of all the constraints that involve the problem occurs, researching all possible alternatives and defining the goals and objectives. The second phase - synthesis, is the generating phase of possible solutions to solve the problem. The last phase - evaluation, is where the solution is tested and its performance against expectations is evaluated. Although John Chris Jones presented a linear theoretical model, the practice of Design tells us that it does not correspond to reality. The Design process is a non-linear process. It is a process with advances and setbacks, self-feeding, in search of the best solution. The fact that there is a step backwards at a certain stage does not mean something negative, but rather the understanding of the perception of lack of information or, simply, the realization that the solution achieved does not respond in the best way to the defined problem. Lawson (2006) denounces: "Even more disappointing is the experience common to all designers, where it is only when they present possible solutions to their customers that they perceive that they have misrepresented the problem" (Lawson, 2006, p. 35) [6].

Mozota (2003) [7], is surgical on the problem of non-linearity in the design process. “Knowledge in design has a tacit nature, and instead of presenting the design process as a sequential vertical model, it is perhaps more correct to represent it as a wheel.” (Mozota, 2003, p. 18) [7]. Thus, it becomes clear that the Design process must be represented in a circular and non-linear way to underline its recurrent nature. Brigitte Borja De Mozota's theory is central to future representations of the designers' work model.

4. Case Study - Italdesign: the Giugiaro and Mantovani Masters

“Take the genius and non-conformism of the designer, add the pragmatism and logic of the engineer, and you have Italdesign, a cocktail of creativity and technology.” (Ciferri, 1998, p. 7) [8].

Italdesign was born from a meeting between two men who decided to unite their professional resources, around a common goal - Giorgetto Giugiaro and Aldo Mantovani. Through a sheer vision, they became pioneers of a new strategy that established the first true service company for the automotive industry. As Giugiaro and Mantovani themselves sum up, "We are a small version of a large automobile manufacturer (...) We are not competitors, but external partners, we provide a working group that can be deployed when a builder's internal resources are insufficient for the design of a new vehicle, either in its entirety or for only a few intermediate stages and has to be ordered from third parties " (Ciferri, 1998, p. 7) [8].

Italdesign is currently focused on excellence providing services to the automotive industry, where simultaneous engineering and outsourcing have become the mantra of this industry. Forty-five years ago, at the Italdesign foundation, Giugiaro and Mantovani realized that the automotive industry was structured in a highly verticalized way in which, each department would guard with devotion its autonomy. From an initial vision to a millionaire business. Over the last few years, Italdesign's technological bets have been on new simulation tools (virtual reality and CAE (3) and rapid prototyping: soft tooling (4) and 3D printing (5).

Italdesign was officially founded on February 13, 1968. Initially as SIRP (Italian Society for Realization of Prototypes) to be later changed to Italdesign at the suggestion of Giorgetto Giugiaro. As Alfieri (1999) [9] explains, “Ital Design, ‘Ital’ because the projection was the world market, ‘Design’ not only because the term was fashionable but also because it fully expressed the approach to the work that he wished to undertake by extending himself to the production of consumer and semi-durable goods and services.” (Alfieri, 1999, p. 29) [9].

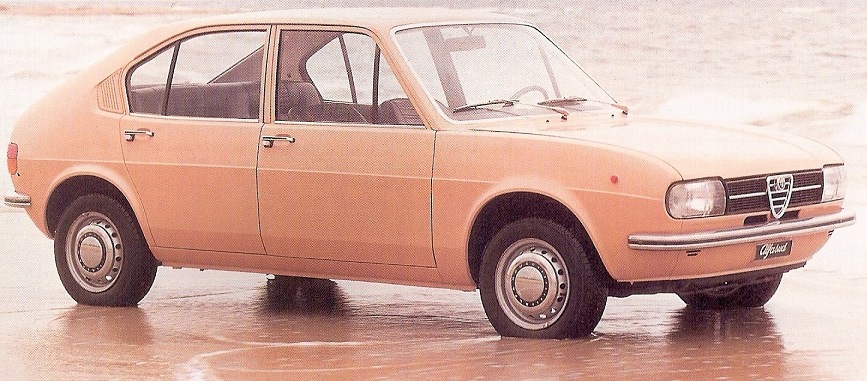

The work at Italdesign began with some orders from Japan: a study for a compact four-seater for Suzuki and a minivan for the same manufacturer. However, it was by this time that one of the first large projects awarded to Italdesign was beginning to take shape - the Alfa Romeo AlfaSud - Fig. 3.

In 1967, Alfa Romeo's former board member, Giuseppe Luraghi, in agreement with IRI (6), launched a project for a new plant in southern Italy located in Pomigliano d'Arco, Campania, near Naples. At that time, this region suffered a huge economic depression with a high rate of unemployment. It was then, under the tutelage of the German engineer and project leader Rudolf Hruska (7) that Italdesign began its Design process managed by Giugiaro and Mantovani, from the moment of conception to the beginning of production on the assembly line. As Giugiaro recalls, “I still like Alfasud very much. (...) It was the first car we followed from A to Z. It was not just a style exercise like the others we had developed up until then, but a project that we at Italdesign had to design and transform on the assembly line by our initiative. Always under the guidance of Rudolf Hruska, we have been able to achieve new standards in terms of passenger, compartment space and, cargo capacity." (Vann, 2005, p. 112) [10]. In fact, the space of the passenger compartment was outstanding and became a reference, for the automobiles of this range for other manufacturers.

For example, Giugiaro placed 1770 mm between the brake pedal and the lumbar support, on the back of the driver's seat, an exceptional number for a small family member of this range. Another formal feature of the Giugiaro Design in this vehicle was, through the extension of the roof, created more space for passengers in the rear seat, making it fall behind the window to the rear cut, one of the formal lines that so well characterized the design of Giugiaro, during the following decades.

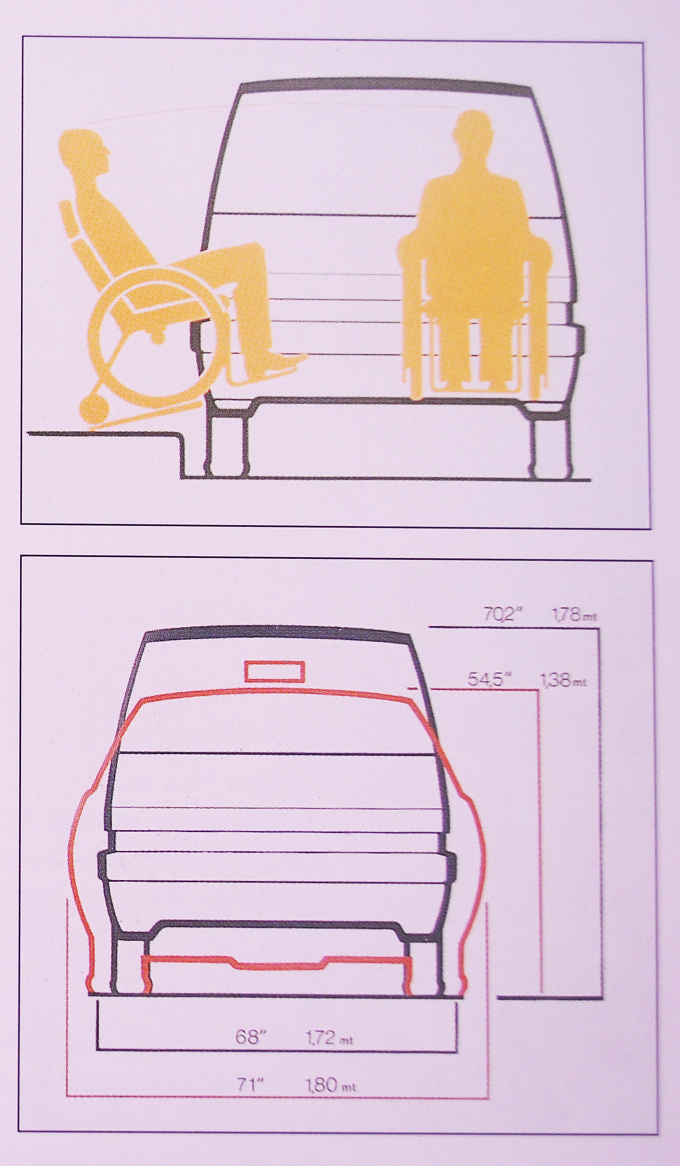

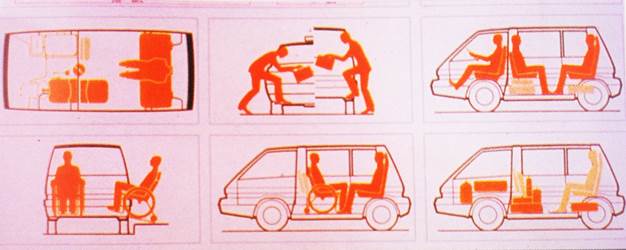

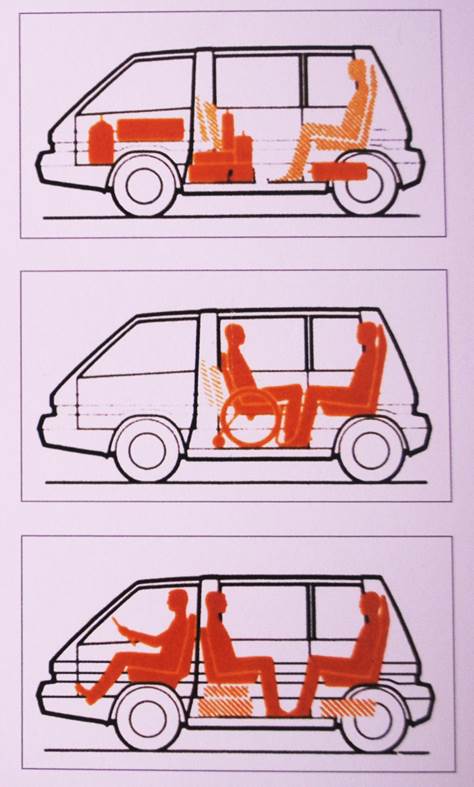

Following the invitation of the Museum of Modern Art in New York in 1976, Italdesign participates in a project entitled - The Taxi Project: Realistic Solutions for Today. This was the opportunity for Giugiaro to renew his design thinking. For this project, the prerequisites would be to transform the New York taxi into a compact, ergonomic vehicle (for passengers and driver), reduce fuel consumption and pollutant emissions. As Giugiaro reveals, “At the time ... I began to be interested in new problems, the solutions of which were fulfilled in the following years. The compact vehicles have come up with greater habitability, with vertical passenger seats, optimized visibility and, therefore, greater safety on the road. Today, these concepts seem to us normal, but the moment they emerged they were seen as revolutionary and futuristic, but often considered with skepticism and even irony.” (Vann, 2005, p.31) [10]. Giugiaro managed to optimize the available space in order to transport five passengers and driver, more space for luggage. Access would be through a sliding door that would allow access, to disabled people or baby carriages - Fig. 4, Fig. 5 and Fig. 6.

The added value from the success of the high quality of Italdesign's products and services over more than forty years of activity has been the close relationship between style and engineering throughout the Design process from conception to realization. In this way, the engineering department of the company aims to follow the Design process, ensuring that they meet the quality specifications of the customers. Thus, engineering aims to analyze the feasibility, functionality, and structural integrity throughout the Design process, working closely with the style department. In order to reduce the product development cycle (both in time and in cost), the starting point for a good Design must, in addition to an attractive formal composition, be materializable.

Over forty years, Italdesign’s developed method is based, as already mentioned, on a strong integration of the different departments. It allows the optimization of the Design process by creating synergies between the different areas of knowledge, be they style, engineering, testing, or methods, with the goal of reducing the total number of prototypes, design process deadlines and technical risks.

The main competitive advantage of Italdesign's working model is undoubtedly to provide car manufacturers with the complete development of cars up to the start of series production. Soon, Giorgietto Giugiaro realized how the automotive technology evolved as well as the management by the main manufacturers. The invitation to Aldo Mantovani for the Italdesign foundation not only denounced a vision of the future of the automobile industry, but also the deep knowledge about automobile Design Giugiaro possessed.

The role of engineering in Italdesign is not only an integral part of the Design process, but also a cross-departmental service, providing technical support and valuable fundamental inputs for success in terms of feasibility, cost, and time. The support of engineering is thus the guarantee of the overall quality of the project, intervening in the different stages of validation of the project until the beginning of the series production at the customer's final assembly factory.

5. Conclusions

Design is a language that requires processes. To understand, the way engineering complements and supports the Design activity, the Design process was explored. In fact, the different processes of Design are nothing more than attempts to describe a whole systematization of what Design is. Thus, it is through the segmentation of activities and their interconnections that it is possible to assimilate the relations and tensions between the different stages, composing the different Design processes. Therefore, only through this way, it would be possible to show where, when, and how Engineering may be present, having a clear view of the relations between them. It interprets Design as a process and as a creative discipline par excellence, but without Engineering's support it can easily fall into a feasibility trap. That is, this duality in the design affinity of the two disciplines is viewed in a complementary way and never in an isolated or conflicted way.

To analyze the present case study in this paper, it is best to divide the Automobile Design in two different fields, the automobile Design as a product and as a process.

Italdesign was founded by two men: a Designer and an Engineer. Most innovations introduced in car Design from Giugiaro were related to space and habitability of the interior. But the 1976 New York Taxi marked a decisive turnaround in Giugiaro’s design philosophy. On this concept, styling gives way to ergonomics and comfort. “It was the start of a search for better internal driving space by raising height and reducing impact with the ground” (Alfieri, 1999, p. 43) [9].

Italdesign was the first company where Design met Engineering and revolutionized the automotive product development process. The inflexible and uncompromising styling and engineering structures of the automotive main manufacturers gives them a huge lag on their product development process and very complex and heavy structures to manage.

In fact, Italdesign, doing full automobile development, soon realized that the connection between Design and Engineering could bring a strong competitive advantage. This advantage was so expressive that Italdesign irrefutably influenced the automobile product as we know it today. However, Engineering's role in Italdesign is not only an integral part of its design process, but also a service that is transversal to all areas, supporting them technically and contributing successfully to the fulfillment of the different commitments with its stakeholders.

However, the aim of this paper is to shed some light on a definition for the product development process, from the Design and Engineering point of view. Both, Design and Engineering disciplines are complementary on the product development activities and should not overlap.

Notes

ABET - Accreditation Board for Engineering and Technology.

RFP - Request for Proposal.

CAE - Computer Aided Engineering.

Molds or Tools used to build parts or subassemblies for product validation in the early stages of pre-series builds.

3D printing - processes in which material is joined or solidified under computer control to create a three-dimensional object.

The Instituto per la Ricostruzione Industriale - IRI, was an Italian public holding company established in 1933 by the fascist regime to rescue, restructure and finance banks and private companies that went bankrupt during the Great Depression. After the Second World War, IRI played a pivotal role in the Italian economic miracle of the 1950s and 1960s. It was dissolved in 2000.

Rudolf Hruska (Vienna, 2 July 1915 - Turin, 4 December 1995) was an Austrian automobile designer and engineer, most famous for his design of various Alfa Romeo cars.