INTRODUCTION

Nowadays, it is essential that the strategies for closing tailings deposits and recovering of other areas with contaminated soils are based on sustainability, allowing cost reduction during and after the mine closure. Thus, sustainable planning of mining areas must include its rehabilitation to other land uses which promote the regional socio-economic valorisation. The implementation of pasture or intercropping with non-food autochthonous plants with added value is a promising option (Santos et al., 2018, 2020; Arán et al., 2020, 2021).

The inoculation with arbuscular mycorrhizal fungi (AMF) and other beneficial soil-borne microorganisms (e.g. Trichoderma) has become a popular technique that can improve the fitness of diverse plant species under stress conditions (Coninx et al., 2017; Fernández-Fuego et al., 2017), and consequently, the environmental recovery of degraded areas. Nonetheless, the germination and development of a plant cover, even with autochthonous species, directly on mine tailings generators of acid drainage is impossible (Santos et al., 2016). Therefore, an essential part in environmental rehabilitation plan is the chemical improvement of tailing materials and their leachates in order to support a plant cover which will also contribute to the environmental recovery processes (Santos et al., 2016; Arán et al., 2021).

Previous studies, under greenhouse and field conditions, already explored ways to improve bio-physico-chemical properties of sulfide mine tailings and the biomass yield of several plant species (e.g. Santos et al., 2018; Arán et al., 2020, 2021).

In this context, the current experiments aimed to advance the knowledge about the recovery and valorization of mining areas and agro-industrial wastes by the implementation of productive crops. The current study focuses on the effect of a designed Technosol with/without microbial inoculant (arbuscular mycorrhizal fungus+Trichoderma) on environmental rehabilitation of sulfide tailings and their leachates as well as herbaceous cover development for pasture or intercropping with aromatic and medicinal plants.

MATERIAL AND METHODS

Composite samples of a sulfide tailing with a fine texture were collected, in a deposit from Aznalcollar mining area (Los Frailes Mining Company, S of Spain, Seville province), and analysed chemically in order to evaluate the key needs to be recovered. For the elaboration of the designed Technosol, several agro-industrial wastes, namely from pulp paper industry, were used.

The proportion of Technosol applied to sulfide tailing was evaluated, in batch assay under controlled conditions, through its mixture in increasing doses (m:m) and the monitoring of pH and electric conductivity in water (1:20; m:V) along the time (from 10 min until 48 h). After selection of the application rate of Technosol, a microcosm assay (≈3 kg of material per pot) was carried out, under controlled and greenhouse conditions. Three treatments were stablished (n=6, 18 pots in total): sulfide tailing with MI; Technosol+sulfide tailing with MI, and Technosol+sulfide tailing without MI. The Technosol and the sulfide tailing were mixed manually. One month after incubation of the materials, ≈13 g/plot of a comercial mixture of herbaceous species (graminaceous and legumes) were sown and a comercial MI (mixture of mycorrhizal fungus Rhizoglomus irregulare and Trichoderma) was applied. All pots were maintened at 70% of water-holding capacity under greenhouse-controlled conditions for eight months. Two rounds of biomass collection were conducted in consecutive order: five and eight months after sowing. During the assay, visual aspects and plant cover development were monitored and, at each sampling, dry shoot biomass of the herbaceous plants was evaluated.

Germination tests in filter paper (n=6) for the herbaceous mix used in the pot assay were conducted in a growth chamber, under the conditions of 16 h of light at 25±1 ºC and 8 h of darkness at 20±1 ºC. The germination rate was determined for 17 days being the criterion of germination the emergence of a radicle.

The Technosol, sulfide tailing and Technosol+sulfide tailing (fractions <2 mm) were characterized for: pH, Eh and electrical conductivity (1:2.5 m:V); extractable P (Olsen method); total N (LECO analyser), organic C by wet digestion (Springer & Klee, 1954) and cation exchange capacity (Peech et al., 1947). Multielementar concentration was determined by ICP-MS in pseudototal fraction (Aqua regia extraction) and simulated pore water.

RESULTS AND DISCUSSION

Sulfide tailings presented acid and oxidant conditions (pH ≈2.7 and 468 mV) and small fertility characterised by very low concentrations of organic C (<2 g/kg), total N (0.2 g/kg) and extractable P (0.4 mg/kg). Furthermore, total concentrations of several potentially hazardous elements (PHE) exceeded the maximum admisible values for distinct land uses (g/kg - S: 60.1, Fe: 54.1, Cu: 0.16, Zn: 1.3, As: 0.63, Sb: 0.04, Pb: 4.1). The high reactivity of these materials contributed to acid leachates (pH≈2.6) rich-in sulfates (2.2 g/L) and same PHE.

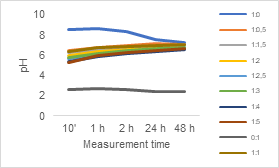

Taking into account the reactivity and chemical characteristics of sulfide tailings and their leachates as well as the fact that these materials cannot support a productive plant cover, the Technosol was designed, especially, with alkaline (pH≈9.4) and eutrophic properties. Through batch assay, it was confirmed the high acid neutralization capacity of the Technosol along the time even with small application rates (Figure 1).

Based on batch assay, the ratio of 1:2.5 (Technosol:sulfide tailing) was deemed to present stabilized and most suitable pH and electric conductivity levels for the plant species to be used in the crop system (e.g. with medicinal an aromatic properties) and future valorization of their high-value extracts. This particular ratio presented pH gradually increasing from 5.63 to 6.72 (Figure 1) and a sudden drop in electric conductivity after one hour followed by its stabilization ≈4 dS/m.

Figure 1 Evolution of pH for different proportions Technosol and Sulfide tailings (labels on the right represent the ratios).

The designed Technosol improved chemical characteristics having positive recovery impacts on sulfide tailings. After one month of incubation, this material reached a pH value of 8.30 with Technosol application compared to 2.75 in the Sulfide tailings, indicating the maintenance of acid neutralization capacity of the Technosol. The Technosol also contributed to an improvement in organic C concentration, reaching 18.55 g/kg, and availability of nutrients (e.g. Ca, K, P, N; increases between 1.5 and >10-folds in simulated pore water depending on element and compared to sulfide tailing). Moreover, PHE concentrations, such as As, Fe, Cu, Pb, Zn, in pore waters were largely decreased with Technosol (>19-fold for As and Pb, >71-fold for Cu, >1124-fold for Zn, and >2850-fold for Fe), compared to those from sulfide tailing (mg/L - As: 13.5, Fe: 342, Cu: 38.5, Pb: 19.3, Zn: 506).

After 17 days, the germination rate in filter paper of the comercial herbaceous mixture was small, ranging between 18.9% and 22.6%. These data recommend the use of a greater amount of seeds for obtaining a more or less dense vegetation cover.

The pot assay was crucial in testing whether inoculation applied to the herbaceous cover was sufficient or not. In sulfide tailing, no germination occurred while in treatments with Technosol application it was similar to the one obtained in germination test with filter paper. Visual observations of the herbaceous biomass indicated no signals of phytotoxicity or nutritional deficiencies such as unusual colors, deformations or irregularities in the leaves’ resistance.

No significant differences in the biomass yields, based on inoculation in either of the two growth cycles, were obtained. However, non-inoculated pots presented higher variability in the biomass yield. In the first growth cycle, inoculated plant pots produced 0.66±0.45 g/pot while in non-inoculated plant pots it was 0.87±0.89 g/pot. In the second crop, biomas yields in both treatments increased and intra-variabililty decreased (g/pot, inoculated: 0.91±0.25, non-inoculated: 1.07±0.47).

CONCLUSION

Carefully selecting and combining wastes, which complement each other’s properties, for the elaboration of designed Technosols is a valuable and efficient way for the rehabilitation and valorization of sulfide tailing deposits to productive areas, as well as for agro-industrial waste valorization. The designed Technosol contributed to a significant improvement in several physico-chemical properties of sulfide tailings and their leachates, allowing the germination and development of a vigorous herbaceous plant cover without visual symptoms of phytotoxicty and nutritional deficiencies. The obtained data is important since that tailing deposit could be valorized to pasture or herbaceous intercropped with plants with added value.

The influence of the selected microbial-inoculant treatment was not evident on the improvement of the biomass yield in the sulfide tailing recovered in the Technosol. Future analyses are ongoing to also determine the phytostabilization effects and potential impact of the microbial-inoculant on elementar composition of the biomass.